-

OEM suppliers must manage precision, cost, and risk effectively. They succeed by delivering high-quality parts on time and maintaining stable supply chains.

-

Stakeholder has different needs, and they all value reliability. Procurement requires transparency, engineers need quick prototypes, operations seek scalability, QA verifies certifications, finance tracks costs, and executives focus on resilience.

-

Good communication sets suppliers apart. Local manufacturers make it easier to work together in the same time zone. Global suppliers can face delays from language and cultural differences.

-

Lead times can differ a lot. Domestic manufacturers can make changes in a day or two. Overseas suppliers require additional time due to shipping, customs, and other factors.

-

Quality control is simpler with local suppliers. It's easy to set up on-site inspections and first-article reviews. With global suppliers, oversight often depends on digital reports.

-

Local manufacturers are more flexible. They handle quick design changes and small orders well. Global suppliers are often better suited for large production runs but tend to be less agile.

-

Comparing costs can be tricky. Offshore quotes may appear 15 to 30 percent cheaper, but additional fees, such as shipping, tariffs, and rework, can erode those savings.

-

Supply chain risk depends on the circumstances. Local sourcing reduces the risk associated with geopolitical events. Global sourcing adds diversity but can bring international disruptions.

-

Customer perception matters. Making products domestically supports 'Made in USA' branding and sustainability. Global sourcing can boost international credibility but may not build as much local trust.

-

Utilizing local and global suppliers enhances an organization's resilience. Local suppliers help with quick prototypes and urgent needs, while global partners offer scalability and cost savings.

OEM suppliers play a central role in manufacturing. You’re expected to deliver high-precision parts on time and on budget while managing cost control, quality, and supply chain risks. Everyone on your team, from procurement to engineering, operations, quality, finance, and executive leadership, shares the same goals.

You need reliable production partnerships, minimal lead times, scalable capacity, and strict compliance. In practical terms, this means partnering with CNC contract services that help you maintain consistent quality and meet tight schedules. Achieving these goals strengthens your position with your OEM customers.

Understanding OEM Stakeholder Needs

OEM suppliers often share the same broad objectives, although each stakeholder approaches CNC partnerships with different priorities. This shapes how they evaluate vendors and where they expect support.

- Procurement Managers want reliable vendors with transparent pricing and predictable lead times. They watch for hidden fees and value vendor accountability.

- Design Engineers need fast prototyping and precision machining for complex geometries. Rapid iteration and flexibility to accommodate design changes are critical.

- Operations and Plant Managers demand scalable capacity and minimal downtime. They balance sourcing between local and global shops to keep lines running and respond to urgent needs.

- Quality Assurance Leads require suppliers with the right certifications (e.g., ISO 9001, AS9100) and transparent inspection processes. Clear traceability and minimal rework are top of mind.

- Finance Leaders focus on total cost of ownership and accurate forecasting. They seek cost control, predictable invoicing, and foresight on currency or tariff impacts.

- Executives and Strategists look for resilient supply chains and competitive advantage. They value partnerships that support brand reputation and reduce geopolitical risk.

Each role influences your approach. Taken together, OEM suppliers cannot afford surprises in their supply chain. A robust CNC sourcing plan addresses these needs by combining local agility with global capacity.

Common CNC Supply Chain Challenges

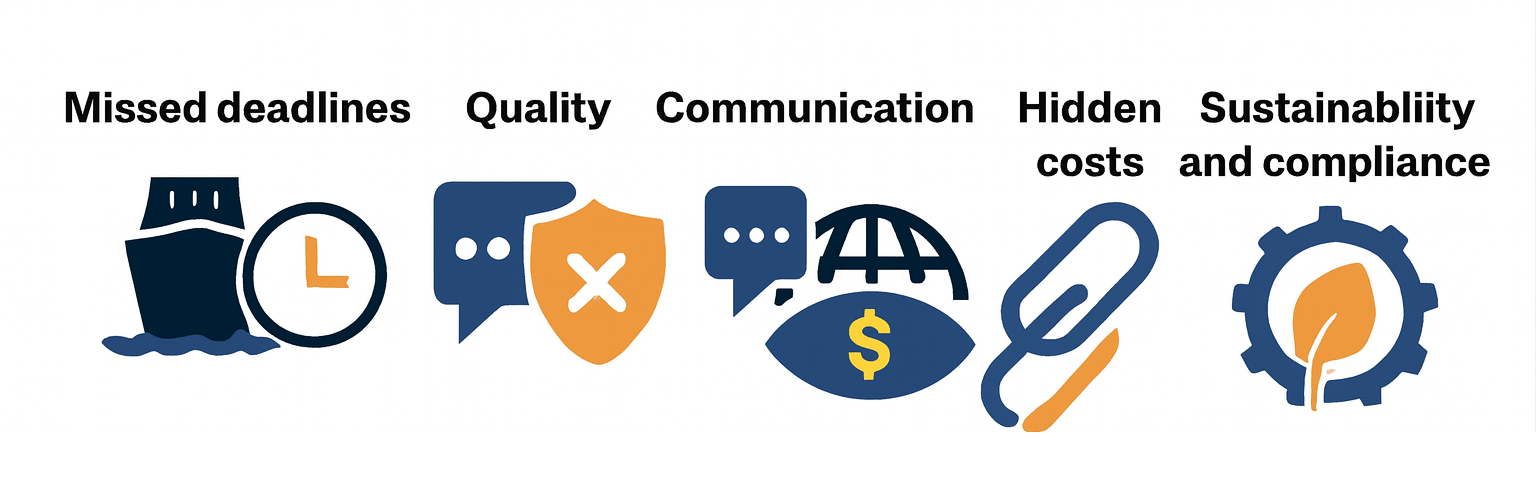

Even with clear goals, OEM suppliers encounter recurring CNC supply chain challenges that affect cost, timing, and production flow. These issues accumulate across projects, making it harder to maintain predictable schedules and consistent quality.

- Unpredictable lead times and missed deadlines. Long transit and production cycles, especially offshore, can disrupt schedules.

- Quality issues and costly rework. Parts returned for defects or out-of-spec tolerances waste time and money.

- Communication barriers with offshore shops. Language differences, cultural gaps, and time zone delays can lead to misunderstandings. One analysis reported that up to 68% of product launch delays stem from communication breakdowns or supplier misalignment.

- Hidden costs and fees. Low offshore quotes often hide extra charges, such as shipping surcharges, customs duties, unexpected tariffs, and special tooling fees. These can quickly erode savings. Industry estimates suggest that hidden expenses can increase project budgets by as much as 27%.

- Limited flexibility for design changes. Once a large overseas order is in production, making changes can be slow and expensive.

- Supply chain disruptions. Local issues, such as labor strikes and energy outages, or global crises like pandemics and trade conflicts, can derail well-planned orders.

- Sustainability and compliance pressures. Environmental regulations and “made in” requirements may favor onshore solutions, while global sourcing can create conflict with sustainability goals.

Low offshore quotes can appear 15–30% cheaper per part. When you factor in shipping, tariffs, transit time, and communication delays, the total cost can exceed that of a domestic option. These added pressures underscore the importance of careful planning and evaluation.

Read → Why US Manufacturers are Turning to Domestic Sourcing for CNC Machined Parts

CNC Machining Solutions for OEMs

CNC machining shops today offer a range of services that extend beyond producing parts. They provide complete solutions that help OEM suppliers manage development cycles, quality, and throughput.

-

Prototyping and Rapid Iteration

Quick-turn machining for design validation and proof-of-concept parts. Domestic prototyping supports fast testing and refinement on tight schedules, and many shops specialize in short-run prototype work to speed up development. -

Precision Production Machining

High-volume production with tight tolerances and repeatable quality. Domestic shops can increase capacity when designs move into production while maintaining consistent specifications. -

Multi-Axis CNC Capabilities

Advanced 3-, 4-, and 5-axis machining for complex geometries. These machines handle contoured surfaces and intricate features in a single setup. -

Material Expertise

In-house machining for a wide range of materials, such as aluminum, steel, titanium, engineering plastics, composites, and specialized alloys. Some providers stock hard-to-find materials for unique applications. -

Secondary Operations and Finishing

On-site services include grinding, deburring, polishing, coating, and heat treating. Some shops also offer build-plate resurfacing or plating in the same facility. -

Assembly and Integration Support

Services for producing sub-assemblies, complete units, or kitted components. Some partners also provide automated assembly or testing solutions to simplify final integration. -

Quality Assurance and Compliance

Comprehensive inspection and documentation. Trusted CNC partners maintain ISO and AS certifications and provide digital inspection reports, NIST traceable calibration, and full traceability for every batch. -

Supply Chain Solutions

Options like vendor-managed inventory (VMI), just-in-time delivery (JIT), and logistics coordination. These help reduce stock levels and increase responsiveness without tying up working capital.

Top-tier CNC shops like PMi2 describe their services as responsive and precise across prototypes, tooling, and production. The right partner adapts capabilities to your OEM needs. They may support your engineering team during prototyping or increase capacity for high-volume production.

Summary of Key Differences

A side-by-side view helps clarify where domestic and overseas machining differ across communication, lead times, quality, flexibility, cost, and supply chain stability.

| Factor | Local CNC Shops – Advantages | Local CNC Shops – Disadvantages | Global CNC Shops – Advantages | Global CNC Shops – Disadvantages |

|---|---|---|---|---|

| Communication | Direct, fast Same time zone |

Limited Language diversity |

Multilingual Global reach |

Time-zone delays Cultural gaps |

| Lead Times | Shorter Turnarounds |

Capacity May be limited |

Scalable For large orders |

Longer shipping times Customs delays |

| Quality Control | Easier On-site inspection |

May lack Specialized certifications |

Advanced processes Broad expertise |

Harder To oversee remotely |

| Flexibility | Quick changes Prototyping |

Higher costs For frequent changes |

Efficient Complex, high-volume runs |

Less agile Small adjustments |

| Cost | Transparent pricing Supports local economy |

Higher labor Overhead costs |

Lower labor costs Economies of scale |

Hidden fees Shipping tariffs, rework |

| Supply Chain Risk | Fewer Geopolitical risks |

Local disruptions Still possible |

Diversified sourcing Options |

Impacted By global disruptions |

| Customer Perception | Strong Local branding |

Limited Global image |

International Credibility |

Less Community-focused |

A balanced approach often works best. Regional CNC providers offer agility and quick response for critical work, while global partners provide scale and cost advantages for large-volume production or specialized materials.

Weighing Hidden Costs and Externalities

Decisions around CNC sourcing often include costs that do not appear in initial quotes. Both local and global partners carry hidden financial and operational trade-offs that can influence project outcomes.

Local CNC Shops

Local shops can bring higher labor and overhead costs, and some may charge premiums for rush orders or small batches. Tooling, fixturing, and certification requirements can increase project budgets by 15–30%. Staffing changes in smaller facilities can also slow production if a key machinist leaves. A practical upside is the contribution to the local economy, along with possible government incentives and a smaller carbon footprint.

Global CNC Shops

Global partners often concentrate hidden costs in logistics. Shipping, customs brokerage, and fluctuating tariffs can raise the landed cost above the initial quote. Quality risks are another factor because defects discovered after delivery may require rework or scrap.

Longer freight cycles also tie up cash in inventory and expose projects to currency swings. International freight contributes to higher carbon output and is affected by fuel prices and policy changes.

A careful review of the total cost of ownership helps OEMs avoid surprises. Labour, logistics, quality control, tariffs, and inventory implications all influence the real cost of a part, and the lowest quoted price can become more expensive once these factors are included.

Achieving Success with a Blended Sourcing Strategy

A combined approach allows OEMs to use the strengths of both local and global CNC suppliers. Local shops handle prototyping, urgent changes, and work that benefits from close collaboration. Many can complete engineering adjustments within 24 to 48 hours.

Global partners are effective for high-volume production, specialized materials, or cost-sensitive components because their scale can reduce unit prices.

A hybrid sourcing model builds resiliency into the supply chain. You have nearby capacity if an overseas vendor encounters delays, and offshore options if local demand increases. This approach maintains stable lead times, predictable costs, and provides access to both agility and high-volume capabilities.

Assessing Your CNC Supplier Mix

Evaluate your CNC partnerships to determine whether your current mix strikes a balance between local responsiveness and global efficiency. Review areas where lead-time or quality issues could be reduced through nearby machining and where offshore capabilities can lower costs.

A structured CNC supplier checklist can help identify hidden expenses and refine your sourcing strategy. The right mix of regional and global partners strengthens production reliability and cost performance.

Machining Services

Quality, accuracy, timely delivery, and innovative problem-solving keep your production on track.

View our capabilities

Frequently Asked Questions

A blended strategy lets you match each project to the partner best suited for it. Local shops offer quick turnaround and hands-on collaboration for prototypes or urgent work, while global suppliers provide scale and lower labor costs for large runs.

Offshore machining can involve additional costs such as long transit times, shipping delays, customs duties, tariffs, and potential quality rework. These factors can reduce the savings from lower labor rates and should be included in total cost calculations.

Local shops provide direct communication, faster lead times, and easier oversight. You can visit the facility, approve tooling in person, and get quicker feedback on design changes. Emergency orders also tend to move faster.

Global CNC partners are well-suited for large-volume production or specialized requirements. They often offer lower labor costs and can handle extensive batch runs or uncommon materials that local shops may not stock.

Look beyond the per-part quote. Confirm certifications such as ISO 9001 or AS9100, review capacity for your volumes, and assess communication practices. Model the total cost of ownership by including logistics, inspection, rework potential, and risk factors. This ensures your chosen partners meet production needs without unexpected expenses.