FANUC Robot & Cobot Integrators

Increased Output, Faster Cycles, and Unmatched Quality

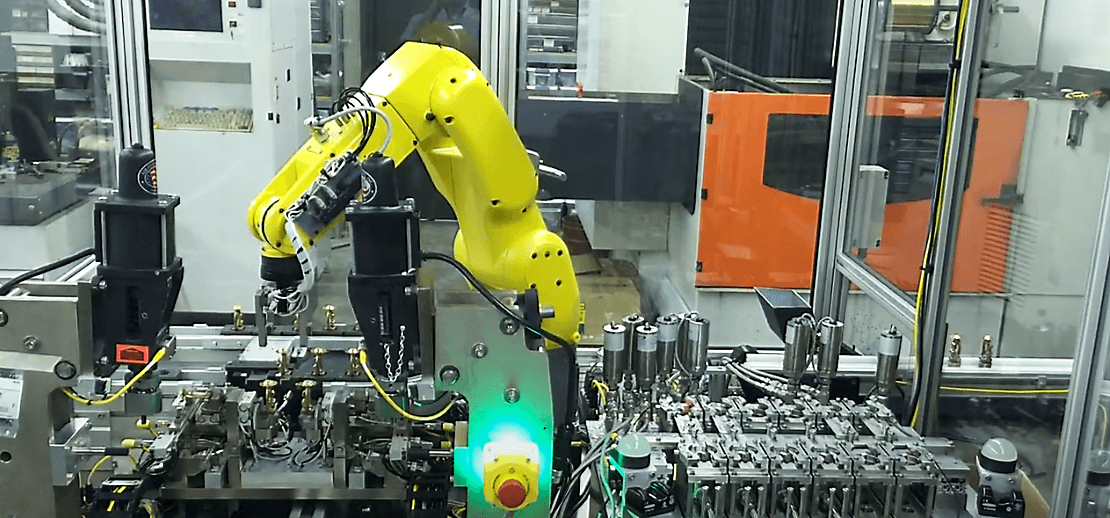

When production demands are growing faster than your workforce, we integrate and automate FANUC robotic solutions that increase uptime, precision, and safety for CNC applications including pick-and-place, testing, and assembly.

FANUC Authorized System Integrators

As an authorized FANUC ASI partner, PMi2 is able to provide enhanced services and support for customers:

- Engineering custom automation systems that integrate FANUC robots, cobots, and vision inspection

- Seamlessly integrating FANUC robotics with CNC, MES, ERP, and PLC systems

- Offering extended warranties, service agreements, and post-installation support

- Leveraging FANUC’s global service network to give you more uptime and scalability

Expert Designed Robotic Automation

Remove Inefficiency That Slows You Down

When you need speed, uptime, and precision, we customize and deploy FANUC robots that pick, sort, and stack with consistency, ensuring your production hits output goals.

- Picking & Packaging

- Material Handling

- Palletizing & Depalletizing

- Secondary Operations

Automate CNC & Machining Applications

Go from Labor Shortage to Lights-Out Production

When you need reliable automation that scales with demand, our FANUC robotic solutions load, cut, and finish with precision, so your team operates CNC systems more confidently and achieves "lights out" 24/7 production.

- Machine Tending

- CNC Milling, Turning, Grinding

- 5-Axis Machining

- Laser Cutting & Complex Machining

Add Smart Automation & Vision Systems

Automate With Insight, Not Just Motion

You need automation that thinks ahead. We integrate FANUC vision and simulation tools so your team can catch defects, prevent downtime, and program confidently before the first part runs.

- iRVision

- Zero Down Time (ZDT)

- ROBOGUIDE Simulation

What's Driving Robotic Automation

From Goals to Gaps, We Help You Close the Distance

You're chasing throughput, precision, and uptime, while battling labor gaps, supply-chain volatility, legacy systems, and pressure to digitize. As a trusted FANUC robotics partner, we help clear the path with automation built to scale, adapt, and deliver.

What You're Trying

|

Why You

|

What's Holding

|

|---|---|---|

| Increase throughput and reduce cycle time | Pressure to meet demand with limited labor | Lack of internal robotics expertise |

| Improve product quality and consistency | Desire to reduce manual variability | Integration risk with legacy systems |

| Automate repetitive or hazardous tasks | Executive mandates to digitize and automate | Unclear ROI or payback timelines |

| Integrate seamlessly with PLC, MES, ERP, CNC | Preference for a stable robotics platform | Overwhelming vendor landscape |

| Reduce scrap, rework, and downtime | Urgency to solve bottlenecks and quality issues | Post-installation support concerns |

| Ensure compliance and traceability | Fill employment gaps without compromising output | Budget constraints and customization needs |

| Future-proof operations with scalable automation | Need for long-term service and parts availability | Downtime risk during commissioning |

Certifications

It's not just a process and a certificate to hang on the wall. Our commitment to quality, accountability, and security is who we are.

ISO 9001

CMMC Certified

Our FANUC robotic integrations adhere to CMMC cybersecurity protocols that protect your business data and ensure compliance with government and defense standards.

ITAR / DDTC Registered

We're DDTC Registered to navigate complex ITAR defense regulations, ensuring sensitive FANUC automation systems and robotic integrations are protected.

NIST SP800-171

Our compliance with NIST SP 800-171 requirements safeguards the security of any CUI used in non-federal solutions that integrate with FANUC robotics.

Get FANUC-Authorized Experts

Solve Production Challenges With FANUC Robotics

Whether it’s pick-and-place, inspection, or machine tending, we’ll help you deploy fast and reliable automation using FANUC robot and cobot solutions.

Contact UsFAQs About FANUC Robotic Integration

It means you get more than just robots. You get a partner backed by FANUC. As an Authorized Systems Integrator, PMi2 delivers automation that’s custom-engineered, fully supported, and built to scale. You benefit from:

Tailored solutions using FANUC robots, cobots, and vision systems

Seamless integration with CNC, MES, ERP, and PLC platforms

Access to extended warranties and long-term service agreements

Support from FANUC’s global network to maximize uptime and reliability

This partnership ensures your custom designed automation solution runs smoothly, integrates cleanly, and delivers measurable results from day one.

PMi2 supports manufacturers in automotive, oil and gas, defense, electronics, medical manufacturing, additive manufacturing, and industrial products, tailoring each FANUC robotic solution we build to our customer's production goals and environment.

Yes, FANUC robots excel in high-speed, high-precision pick-and-place tasks, especially in electronics, packaging, and material handling.

FANUC iRVision enables automated robots to identify, sort, and inspect parts in real time. This vision-assisted quality inspection reduces defects, improves traceability, and supports flexible automated workflows without requiring extra hardware.

ZDT is FANUC’s predictive maintenance platform. It monitors robot health, flags issues before failure, and helps your team avoid unplanned downtime.

ROBOGUIDE lets you simulate robot motion, cycle times, and part handling before deployment. This reduces commissioning risk and speeds up implementation.

At PMi2, we handle all of the design, programming, integration, and support with our FANUC-certified team, delivering an automated FANUC robotic solution that runs reliably and scales with your business goals.

Yes. FANUC robots integrate with PLCs, MES, ERP, and CNC systems using standard protocols. We design automation that fits your infrastructure.

Once automated robotic solutions are integrated and launched, most production teams see ROI within 12 to 24 months through reduced labor costs, improved throughput, and lower scrap and rework.

Once your FANUC robotic solution is installed, PMi2 offers training, service agreements, and long-term support for customers. As a FANUC Authorized Systems Integrator, we also connect you to FANUC’s global service network.

Yes. We specialize in integrating FANUC robotics with legacy systems, and can help you modernize production operations without replacing your entire infrastructure.

Absolutely. FANUC systems support traceable workflows, vision-based inspection, and secure data logging for highly regulated industries.

FANUC robots support build plate prep, post-processing, and inspection for additive manufacturers. This ensures consistency and throughput without slowing down innovation.

FANUC offers unmatched reliability, native CNC integration, and global support. If you prioritize uptime and long-term serviceability, FANUC is a strong choice.

Start with a conversation. Once we assess your goals, systems, and constraints, then we can design a FANUC-based solution that delivers measurable results.