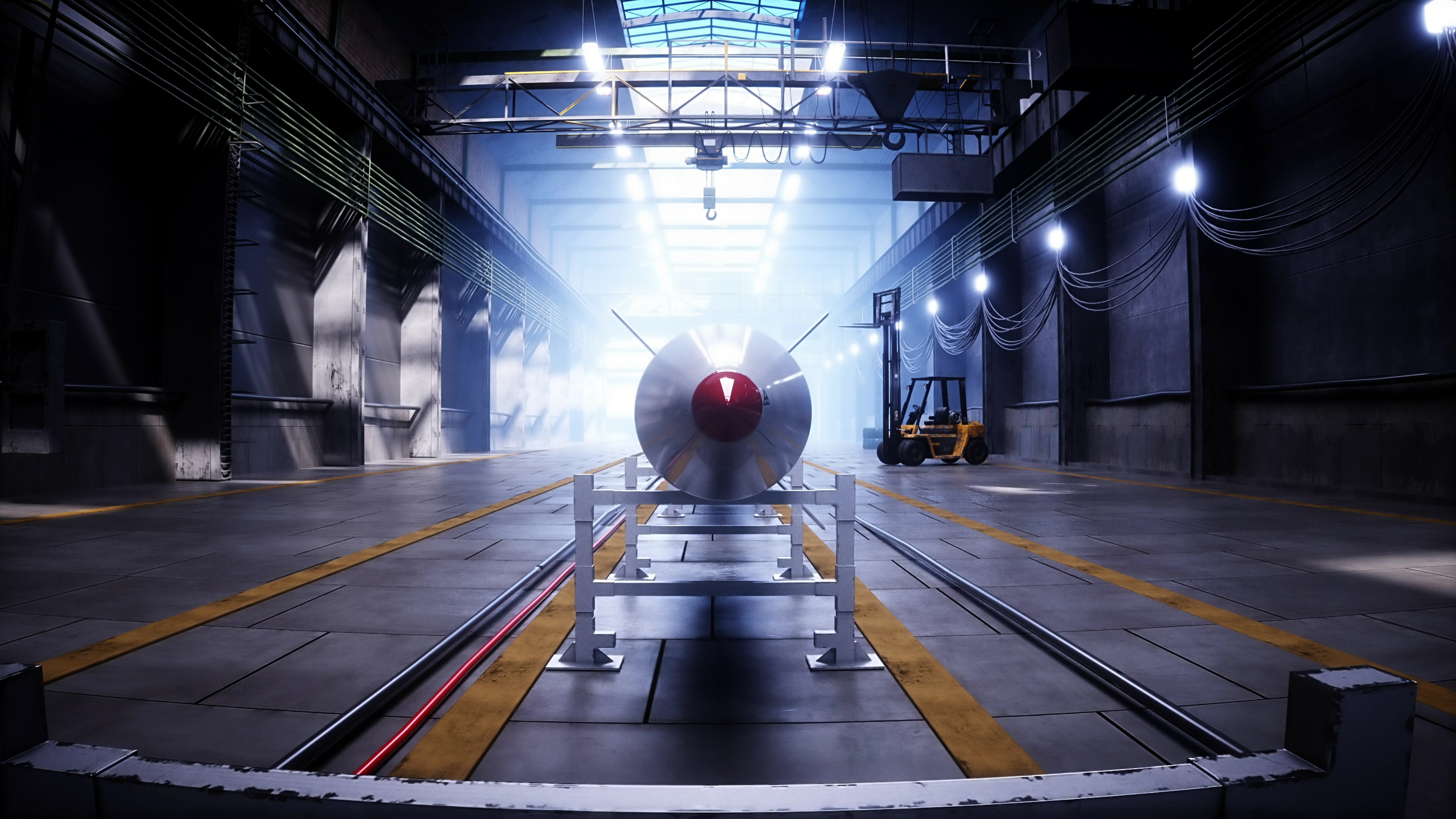

Defense Industry

We know performance and reliability are mission-critical in the Defense sector. PMi2 specializes in delivering precision-manufactured components that meet demanding MIL-SPEC requirements, along with advanced automated systems that streamline production.

Mission-Ready Defense Solutions

Manufacturing Excellence for Every Defense Challenge

We specialize in machining steels and specialty alloys, manufacturing custom components that meet the unique demands of the defense industry. We aim to deliver reliability in the most high-stakes environments.

- Components

- Wire EDM Machining

- Roll and Shaft Manufacturing

- Specialty Tooling

- Quality Planning

- 3 and 4-Axis Milling

- Large Format EDM

- Roll Grinding

- Cylindrical Grinding

- Tool Design and Manufacturing

Strengthening Defense Through Partnerships

-

Defense Contractors

Our facility, equipped with comprehensive CNC tools, ensures precision and faster lead times for the most demanding manufacturing challenges of military components.

-

Infrastructure

Manufacturing durable components for construction machinery and infrastructure projects that support defense installations.

-

Industrial Machinery

We manufacture parts for industrial machinery used in defense manufacturing and production processes.

-

Tool and Die Making

Creating custom molds, dies, and tooling required to produce various defense-related components.

-

Electronics

Producing intricate spot-welding tools for manufacturing advanced electronic systems used in defense, such as circuit boards and connectors.

-

Research

PMi2 supports government and institutional research facilities with our extensive machining, automation, and controls capabilities.

Quality Tracing and Tracking

Assuring Your Success

-

NIST Traceable

By ensuring international standard traceable calibration, we deliver reliable, compliant quality control in every part.

-

Contact CMMs

We provide automated, accurate measurements for complex geometries and inspection reports traceable to NIST standards.

-

Custom Gauging

Custom gauges are built when required to accomplish difficult metrology requirements.

-

Machine Vision CMMs

Deliver fast, precise inspections for flat and edge-detailed components, ensuring compliance with design requirements.

-

Rockwell Hardness Testing

Verify material hardness for superior wear resistance, ensuring longevity and performance of components.

-

Contour Tracing

Captures precise measurements of intricate curves and profiles, confirming parts meet design specifications.

-

Microscribe Arm

Measures precise 3D data with portability and ease, enabling detailed inspections, reverse engineering, and accurate modeling for complex components.

-

Climate-Controlled Gauge Room

Maintaining stable temperature and humidity enables precise measurements and minimizing material expansion or contraction during critical inspections.

-

Profilometers

Assess surface roughness to confirm smoothness, minimizing friction and wear on critical components like bearings and pistons.

Certifications

It's not just a process and a certificate to hang on the wall. It's who we are. Our commitment to quality and security is the only way.

Contact Us

Partner with Defense Manufacturing Experts

Discover innovative manufacturing solutions and advanced systems tailored to meet the demands of national defense.

Contact Us