Additive Build Plate Resurfacing

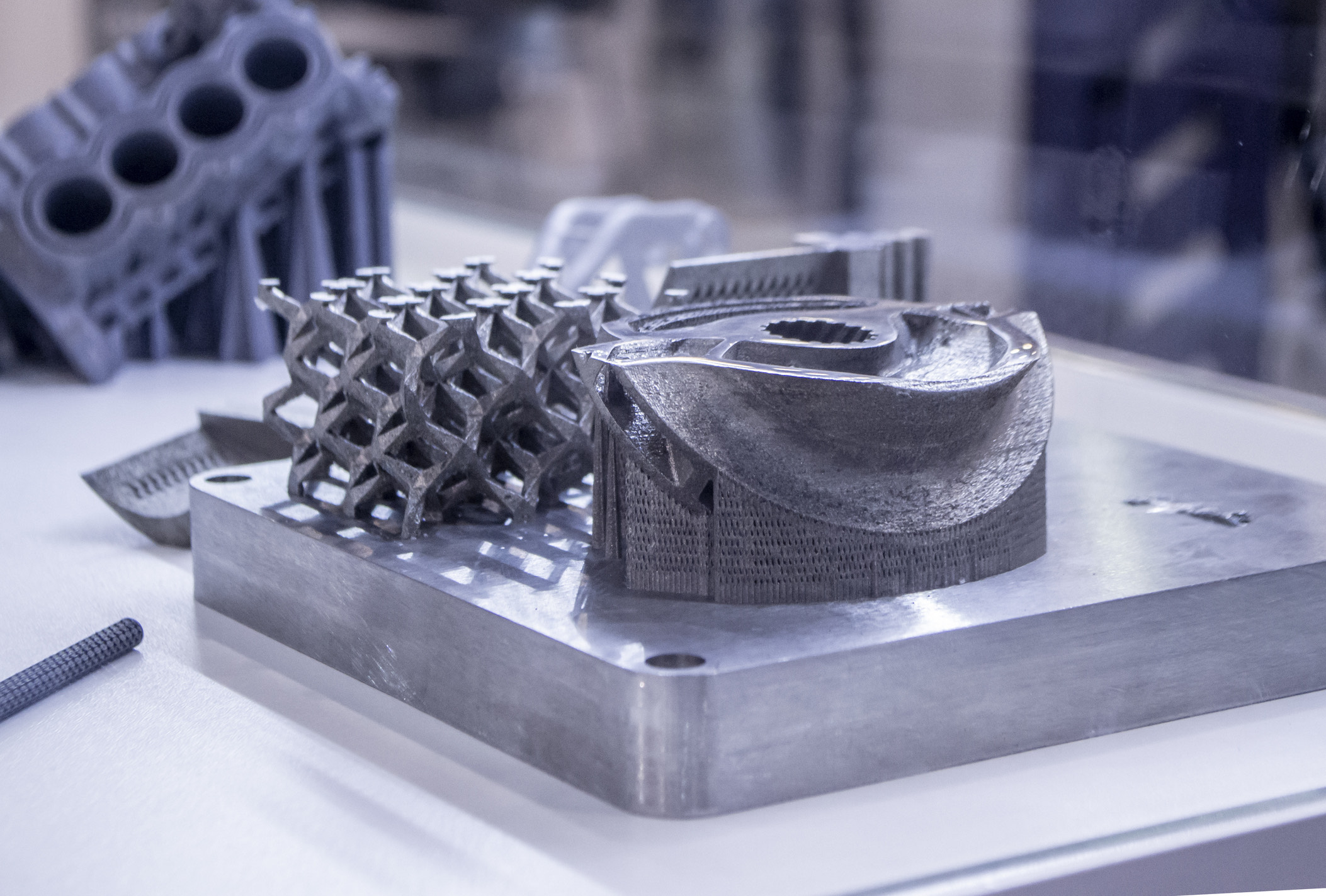

Precision Resurfacing for Metal 3D Printing

We resurface your AM build platforms to unlock business growth and meet tight deadlines, removing residual metals, extending plate lifespan, and ensuring consistent quality for industrial 3D printing applications.

Get More ROI from Your AM Build Plates

We resurface and recondition build plates to enhance profitability for metal additive manufacturers by extending their lifespans and customizing plates for special production needs.

- Customization: We add custom machined features, surface finishes, and geometry to reconditioned build plates based on your requirements.

- Flatness: We use a variety of advanced rotary grinding, surface grinding, and face milling processes to achieve the surface finishes you need.

- Quality Control: We perform extensive quality inspections to ensure resurfaced build plates meet your specifications.

- Roughness: We use CNC milling or grinding to resurface the AM build plate to your specified range of surface roughness.

- Compatibility: We manufacture and resurface build plates to integrate with AM 3D printing equipment such as EOS, Trumph, Nikon, AddUp, and more.

AM Build Plate Customization

Add Custom Features and Geometry

- Hole patterns drilled in the working surface of the build plates to facilitate specific AM printing processes

- Machined islands or other profiles machined into the working surfaces of the plates

- Features to enable quick change build plate fixturing in the additive printing machines

- Material handling and lifting features to facilitate safer and more efficient AM build plate handling

- Thicker than standard plates to increase AM build plate life and to reduce heat related distortion during printing

Benefits for Additive Manufacturers

Results So Good, Resurfaced Plates Feel Like New

-

Maintaining Quality

Resurfacing allows you to maintain smooth, defect-free surfaces that produce high-quality metal prints and reduce wasted material from failed additive builds.

-

Minimize Downtime

Often faster than ordering new, resurfacing helps metal AM shops eliminate production bottlenecks and maintain operational efficiency to meet tight deadlines.

-

Process Control

Through resurfacing, we can customize your platform’s surface characteristics, tailor roughness and modifications, and improve 3D-print success rates.

-

Waste Reduction

Resurfacing reduces material waste, improves resource efficiency, extends the usable life of your build platforms, and minimizes discarded plates.

-

Specialized Solutions

We can resurface your build plates to tackle unique material challenges, optimize processes for exotic alloys, and expand capabilities for advanced metal AM applications.

-

Added Flexibility

Our resurfacing services allow additive manufacturers to scale operations efficiently and overcome limitations without needing outlays for a stream of new plates.

-

Control Costs

We can extend plate lifespans, reduce the frequency of plate replacements, and save on capital expenses, all without compromising quality or ROI for your additive projects.

Metal Additive Manufacturing Partners

Delivering Results for Industrial Additive Applications

We offer a variety of services to support manufacturers who use metal additive 3D printing to produce equipment parts and industrial components with exceptional quality and performance.

- New Build Plates

- Build Plate Customizations

- Secondary Metal AM Operations

- Quality Inspection Systems

- EDM-assisted Parts Separation

- Assembly Automation

- Material Handling Systems

Committed at Every Step

Quality is more than a goal—it's our mission and promise. We deliver precision, performance, and customer satisfaction with every build plate.

Delivering Excellence - Everywhere

From our home in Seneca, South Carolina, PMi2 serves partners across the U.S., Mexico, Europe, and Asia. Our location provides strategic access to major hubs, strong manufacturing networks, and established supply chains.