Manufacturing leaders must rethink ROI models for flex feeding automation and robotic bin picking.

Flex feeding automation and robotic bin picking systems introduce capabilities that go far beyond simple labor savings. Many traditional ROI models still focus too narrowly on labor costs, overlooking the broader impact these systems can have.

Modern flex feeding solutions can transform cost structures, improve uptime, and support business growth. To make informed decisions, leaders need an ROI model that accounts for all these advantages.

Leaders Face High-Mix Realities

Operations directors are constantly reviewing reports and looking for ways to justify investments in technology that can transform their production lines.

Pant managers face the challenge of frequent SKU changes that disrupt workflow, while production engineers work to optimize for a growing number of product variants.

Automation managers advocate for flexible solutions, and VPs want to see clear evidence of bottom-line improvements. Benchmarks for reliable payback, adaptive parts handling, and risk reduction are becoming increasingly important.

Their Priorities

- ROI grounded in real data, spotlighting throughput and OEE lifts

- Flexibility that matches product flux without slowing output

- Reduced risk in unpredictable, high-variety runs

The Core Problem

Many manufacturers face persistent feeding problems and outdated ROI thinking. Frequent jams, downtime, and high retooling costs plague mechanical bowl feeders. Lines struggle with inflexibility on SKU changes and labor shortages, and they rely heavily on costly manual feeding.

Internally, teams grow frustrated by unclear ROI calculations. Finance teams demand justification, and engineers are unsure how throughput gains translate to payback timelines.

Manufacturers deserve automation decisions based on real data, not incomplete models. An outdated ROI model that ignores hidden costs and growth factors leads to misinformed decisions. Companies need a better way to quantify the full value of flex feeding systems.

What Is Flex Feeding & Robotic Bin Picking?

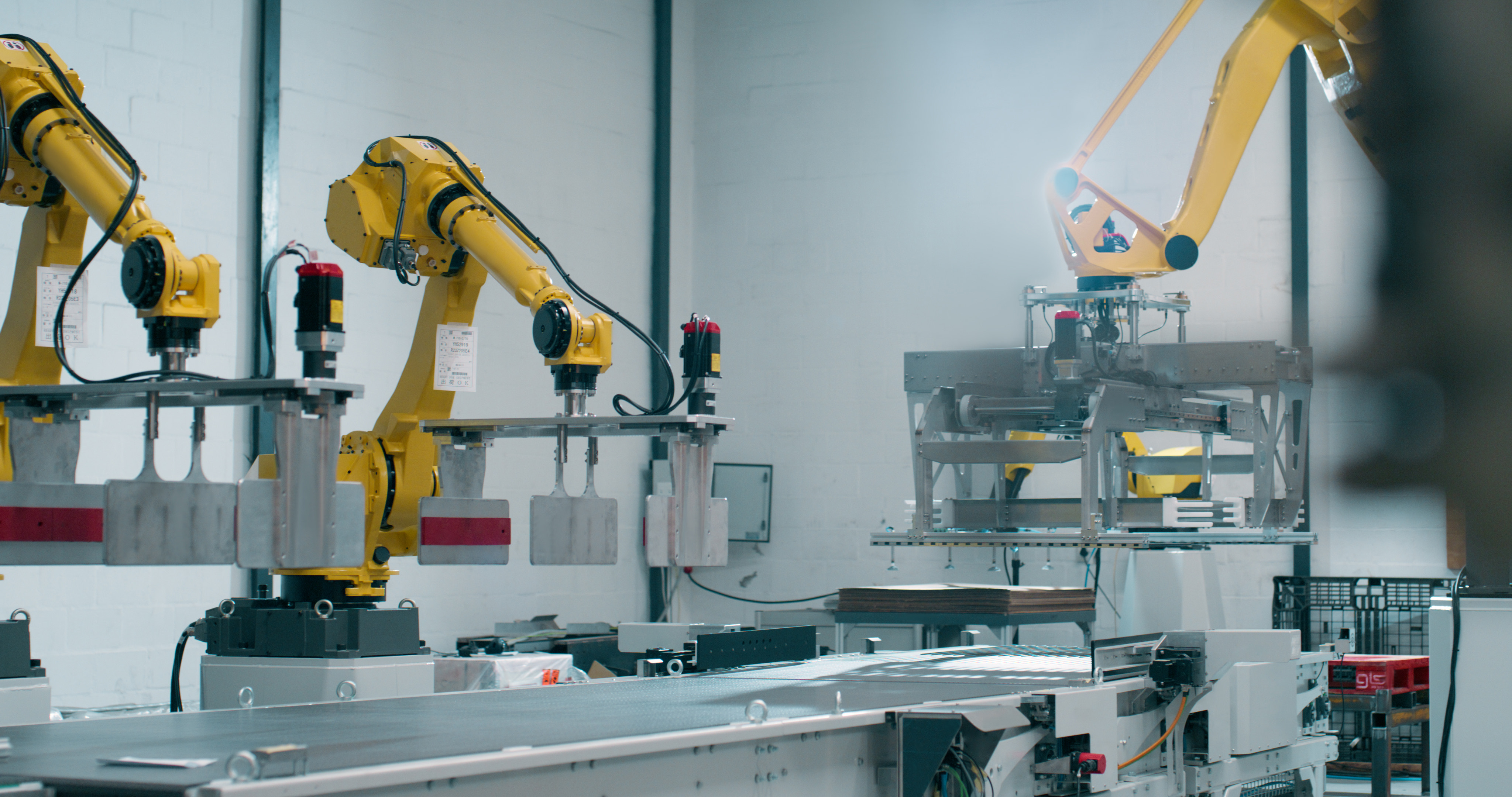

Flex feeding is an advanced manufacturing approach where vision‑guided robots pick parts from bulk bins or trays. Instead of a fixed mechanical feeder tuned to one part, a flexible feeding system can handle many part types through software control. One adaptive robot cell can replace multiple dedicated feeders, reducing the need for mechanical retooling.

This software‑driven, tooling‑free approach lets product changes happen by swapping part programs instead of rebuilding bowls or tracks.

These systems are well-suited for industries like automotive and tier‑supplier production, EV and battery assembly, small‑parts and precision assembly, and general manufacturing environments. They also reshape ROI models because feeding is no longer a fixed cost. Flexibility enables fast changeovers and line scalability.

Key Strengths

- Vision‑guided picking from bulk for high uptime

- One cell can feed many part types

- Software‑controlled flexibility replaces fixed tooling

- Supports high-mix production without costly new feeders

Why Traditional ROI Falls Short

Traditional ROI calculations for feeding automation often overlook the biggest impact areas. Many teams still evaluate systems with outdated assumptions and incomplete cost categories.

Common Pitfalls

- Focusing only on labor, which is often less than 40% of the ROI impact, while ignoring larger efficiency gains

- Overlooking hidden costs Such as changeover downtime, frequent retooling, feeder jams, and the maintenance hours required to keep mechanical systems running

- Misalignment between engineering and finance teams, where throughput improvements do not clearly translate into cash flow and payback timelines

- Judging investments only by upfront cost, even though flexible systems eliminate repeated tooling purchases and reduce downtime over the long term

Outdated ROI models miss half the story. Accurate evaluation requires capturing both savings and revenue-driving gains.

What a Proper ROI Model Should Include

A modern ROI model for flex feeding must evaluate the full operational impact, not just labor reductions. Both direct financial gains and broader performance improvements contribute to payback.

Direct ROI factors

- Labor savings through redeployment rather than manual feeding

- Higher throughput from faster cycles and improved machine utilization

- Reduced scrap when vision catches misfeeds or defects before assembly.

- Less downtime since jams and rebuild-related pauses are minimized

Indirect ROI Factors

- Faster changeovers, completed in software instead of with mechanical rebuilds

- Avoided tooling purchases for each new SKU, since one cell handles many parts

- Flexibility to support high-mix and variable batch sizes without delays

- Improved ergonomics and fewer repetitive task injuries

- Reduced dependence on scarce labor for manual feeding tasks

- Smaller footprint when one flexible cell replaces multiple fixed machines

- Lower maintenance burden compared to bowl feeders that require constant tuning

A model that captures these elements reflects the true whole‑system ROI, instead of hiding value in uncounted categories.

The Right Way to Calculate Automation ROI

A complete ROI calculation must reflect how flex feeding improves productivity, reduces downtime, and supports business growth. When the model includes both operational gains and ongoing costs, leaders get a realistic view of payback and long-term value.

ROI Formula

ROI = (Annual Gains – Annual Costs) / Total Investment

Annual Gains

These include the measurable improvements that drive extra value per year.

• Labor recovered by redeploying operators

• Throughput increases that raise machine utilization

• Scrap reduction through better pick accuracy and part handling

• Downtime avoided by eliminating jams and rebuilds

• Flexibility that prevents recurring tooling purchases

Annual Costs

Operating expenses that keep the system productive, such as maintenance, support, and energy

Payback Period

Payback = Total Investment / Annual Net Gain.

Most flex feeding projects recover their full cost in about 8to 18 months, which is fast for manufacturing automation. Gains in uptime, quality, and production flexibility often account for more than half of the overall ROI.

Automation ROI as a Growth Engine

Flex feeding investments do more than trim labor costs. They let operations unlock the capacity, uptime, and adaptability needed to generate more revenue from the same footprint.

What Growth Looks Like

- Higher capacity utilization because steady, jam-free throughput captures more available production time

- Predictable parts-per-shift that gives sales and planning reliable output to book against

- Faster new product launches thanks to software changeovers instead of mechanical retooling

- Built-in scalability so lines expand volume or product variety without redesigning feeders

- Automation that adapts with demand becomes an engine for additional volume and new opportunities, not a constraint that holds production back.

Custom Automation Solutions

Leverage our decades of expertise to integrate the production automation you need.

Automation Services

Myths vs Facts

Flex feeding decisions often stall due to outdated assumptions. These misconceptions make flexible automation seem riskier or more expensive than it truly is.

✖ Myth

Flex feeding only works in high-mix, complex lines.

✓ Fact

Even stable, medium-volume lines gain value. Jam-free feeding boosts uptime in any environment.

✖ Myth

Bowl feeders are cheaper than robotic flex feeders.

✓ Fact

A bowl feeder may cost less upfront, but over 3–5 years flex feeders typically cost less overall because they avoid rebuilds and downtime.

✖ Myth

Robots will slow down the feeding process.

✓ Fact

Modern vision‑guided robots match or exceed mechanical speeds and avoid stoppages, often raising throughput.

✖ Myth

ROI from automation is only about labor savings.

✓ Fact

Uptime and quality improvements often make up most of the ROI. Labor is only one piece of the gain.

Flex feeding’s value becomes clear once these misconceptions are removed. Leaders see cleaner math and faster payback when real performance data drives evaluation.

What ROI Can Manufacturers Expect

Industry benchmarks show that flex feeding delivers strong financial performance when uptime, quality, and labor redeployment are included in ROI calculations.

How Leading Integrators Approach ROI

Experienced automation partners incorporate ROI analysis from the first conversation. Their proposals account for full-line performance and payback, not just equipment cost.

Key Elements

- Full-system ROI modeling that measures throughput, uptime, and changeover impacts

- Industry-specific knowledge from deployments in automotive, EV, and precision assembly

- Validation through simulation and testing to confirm expected performance and payback

Why Flex Feeding ROI Can’t Be an Afterthought

Manufacturers often prioritize upfront automation costs and may overlook the broader impact of their decisions.

The benefits of flex feeding and robotic bin picking become clear when companies evaluate return on investment in areas like changeovers, labor, uptime, and product flexibility.

An ROI model can help position flex feeding as a contributor to production, capacity, and profit rather than as a simple expense.

If Nothing Changes

Without rethinking ROI models for flex feeding automation and robotic bin picking, manufacturers remain locked into inefficient feeding strategies. Mechanical bowl feeders and manual part feeding continue to cause downtime, feeder jams, and quality issues. Tooling rebuilds and SKU changeovers drive up the total cost of ownership, while reliance on manual labor strains already tight staffing resources.

As product variety increases, rigid feeding systems limit throughput improvement and slow new product introductions. The result is constrained capacity, unpredictable output, and lost revenue opportunities.

If ROI Is Done Right

When manufacturers apply a modern automation ROI model that fully captures the value of vision-guided robotics and robotic part feeding, flex feeding becomes a performance multiplier rather than a cost center.

Lines run with jam-free, stable throughput, enabling measurable gains in OEE and consistent parts-per-shift output. Downtime elimination, scrap reduction, and faster software-based changeovers shorten the automation payback period.

Most importantly, flexible feeding and bin picking automation unlock scalability. New SKUs are introduced without new tooling, throughput increases without expanding floor space, and operating costs decline over time, delivering a strong flex feeding return on investment.

A Transformation That Makes Automation Pay for Itself

Adopting a complete flex feeding ROI model changes how manufacturers evaluate, operate, and scale automation. Decisions become based on measurable outcomes instead of assumptions.

What Changes

Uncertainty becomes confidence as investments are backed by real data

Rigid, feeder-dependent processes shift to scalable, vision-guided flexibility

Retooling delays and downtime give way to reliable, continuous throughput

Feeding evolves from a bottleneck into a platform that supports growth and new products

This approach turns production lines into an asset that grows with the business. Use the Flex Feeding ROI Infographic and Calculator to quantify the impact with your own numbers.

Flex Feeding Automation

Speed, Quality, and Innovation in One Place Machining and automation that drive efficiency in automotive, medical, defense, and more.

Contact UsFAQs

A: Most systems recoup the investment within 8–18 months. High‑volume lines can pay back even faster.

A: No. Medium-volume, steady lines also gain value through fewer jams, faster changeovers and higher uptime. Performance improves in any environment.

A: Upfront equipment costs are higher. Over 3–5 years, however, total cost of ownership is typically lower because one flex feeding cell can handle many parts without new tooling or rebuild-driven downtime.

A: Both direct and indirect improvements. Labor savings, throughput gains, scrap reduction, downtime avoided, faster changeovers, reduced maintenance, improved ergonomics, and better use of floor space.

A: Manufacturing surveys in 2024 reported cost reductions and improved operational agility from automation investments, with many leaders citing strong ROI and rapid payback as primary drivers.

A: Begin by gathering your current feeding data and inputting it into a flex feeding ROI calculator. Quantify the gains to build a solid business case backed by real numbers.

A: No. “Flex feeding” refers to automated part feeding for factories and robotic bin picking, not animal feeding.

A: Your automation integrator can help evaluate ROI and validate performance expectations based on your specific production needs.