Why Copper Is Critical for AI Infrastructure

Builders break ground on AI data centers as often as baristas open coffee shops. Developers race to meet demand for smarter apps and faster cloud access, and copper keeps the whole system running.

A single hyperscale AI data center can require up to 50,000 tons of copper, dwarfing the 5,000–15,000 tons used in a traditional data center. This immense scale of copper infrastructure for AI explains why copper parts are at the heart of modern data center construction.

AI Data Center Growth and Power Density

Hyperscale campuses built by tech giants like Microsoft, Amazon, and Meta are exponentially larger and more power-dense than those of previous generations. Each prioritizes securing a reliable supply of copper-machined parts to meet aggressive build schedules.

AI-driven projects are now straining global manufacturing supply chains. Markets didn’t fully anticipate demand for copper machining for data centers, so suppliers who guarantee on-time production of copper parts hold a strong position.

Copper’s thermal and electrical conductivity

Copper is prized for having some of the best electrical and thermal conductivity among engineering metals. This makes it the material of choice for high-performance power and cooling in AI centers.

It carries huge electrical currents with minimal loss, and it dissipates heat efficiently from server components.

Its thermal transfer properties are likewise top-notch, which is critical as AI chips generate intense heat. Copper cold plates and heat sinks keep these processors cool under heavy loads, and the metal remains stable through constant thermal cycling without degrading or warping. Its machinability and form-factor flexibility mean engineers can design dense, space-optimized systems using copper parts.

Precision at the rack level

The performance demands in AI data centers require extreme precision in manufacturing each copper component. Even slight deviations can increase electrical resistance or cause misalignment. Smooth finishes are equally important because a polished contact surface on a copper busbar minimizes electrical resistance and heat buildup.

Good surface finish also aids in thermal and EMI performance, ensuring there are no hotspots or gaps that could introduce interference.

Because many AI facilities use modular designs, dimensional consistency across builds is vital. Every copper piece must be identical so that modules can be swapped or scaled out without requiring custom adjustments. If a copper component is poorly machined, the risk of failure goes up significantly. In short, precision machining is non-negotiable to achieve the reliability these massive AI data halls require.

Copper’s Role in AI Data Centers

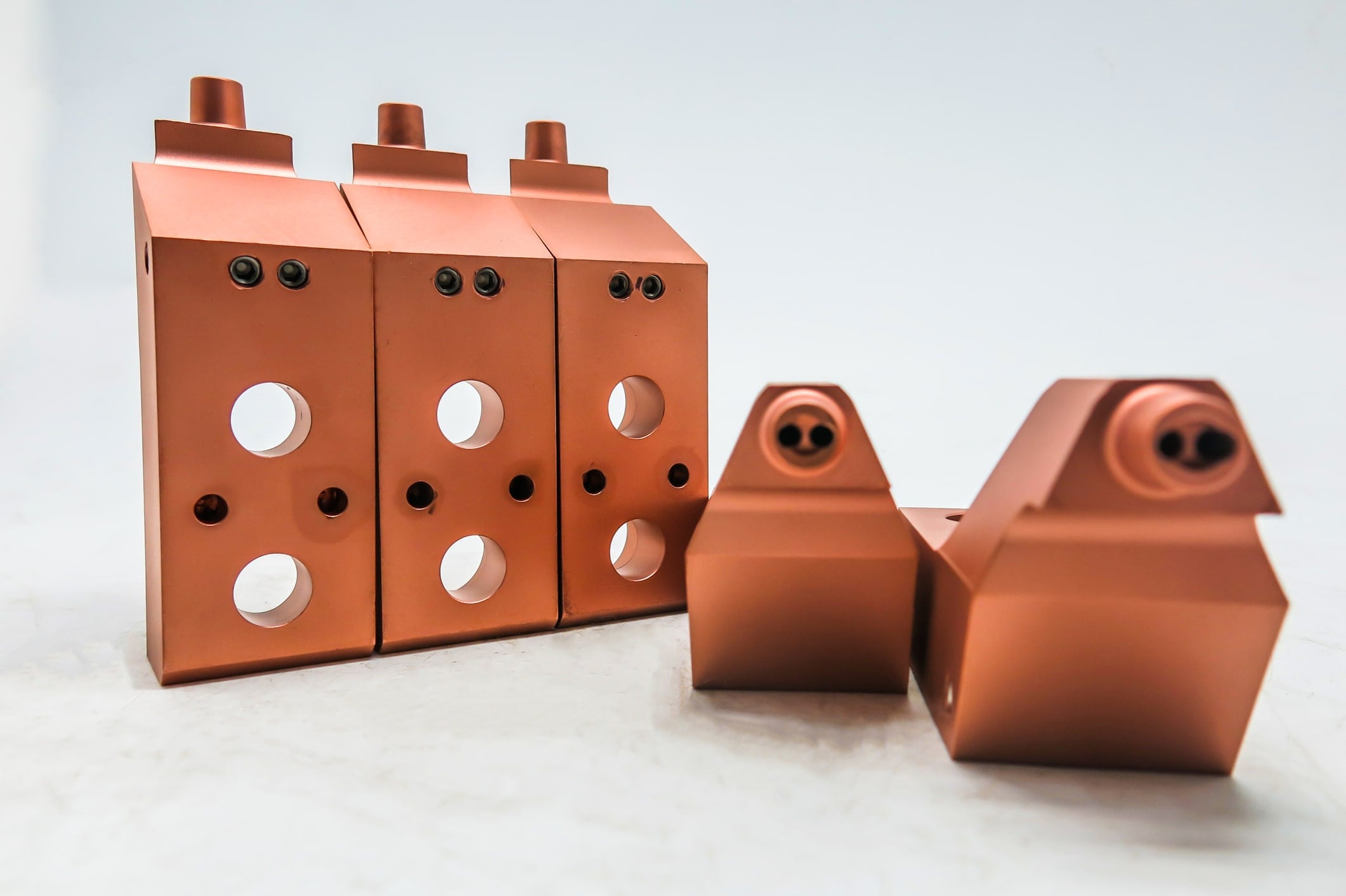

Copper is ubiquitous in the infrastructure of AI data centers. It isn’t just wiring in the walls. Copper forms many of the “copper data components” that enable high-power, high-density computing.

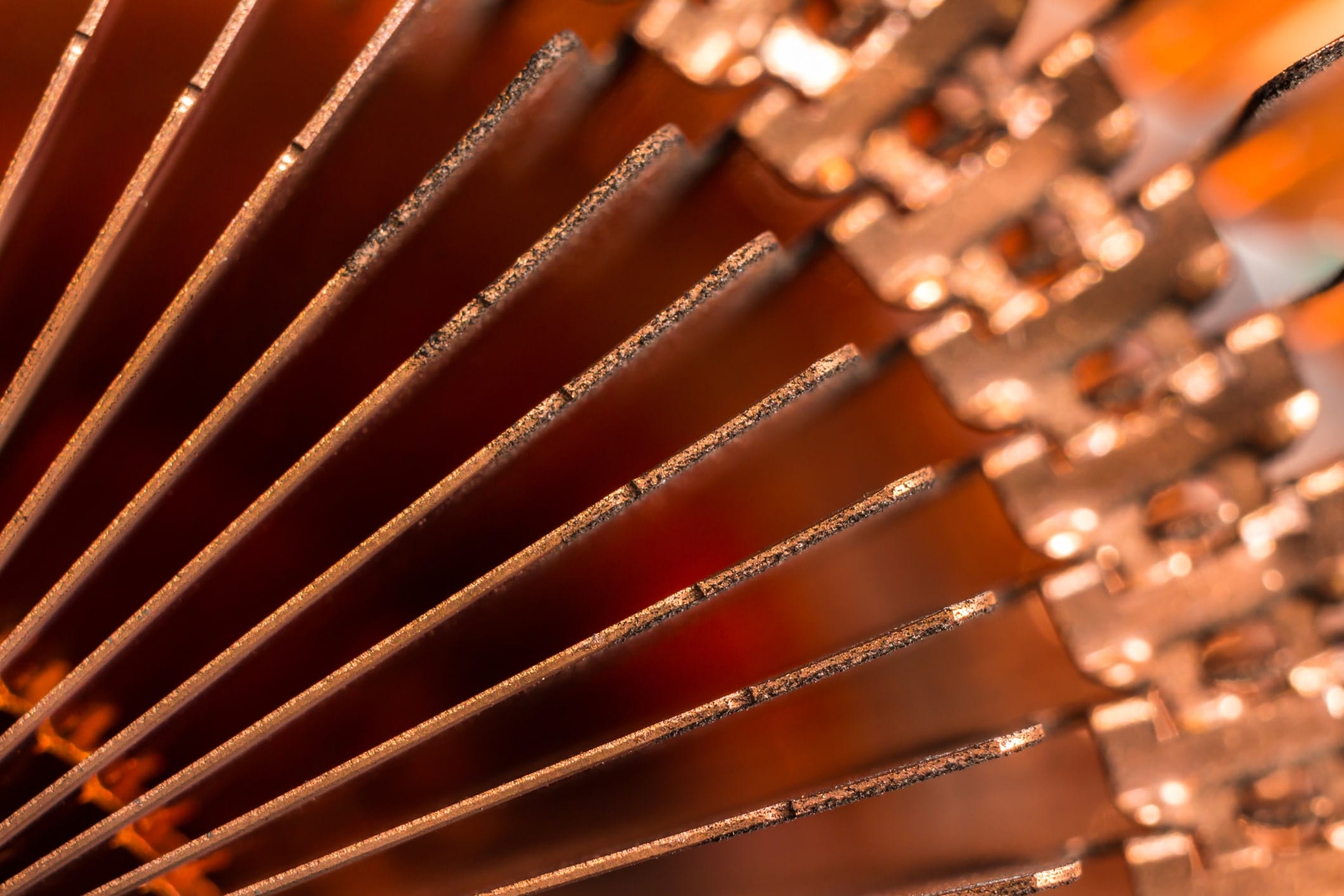

- Power distribution components: Copper is the backbone of data center power delivery. Heavy copper busbars distribute high-current DC power from rectifiers to server racks with minimal voltage drop. Copper connectors and terminals at these busbars form low-resistance junctions for the transfer of electricity. Even within server rack units, copper machined parts, such as custom power rails and grounding straps, ensure electricity flows safely.

- Thermal management components: Cooling an AI data center is just as critical as powering it, and copper plays a starring role. Copper cold plates are widely used for direct liquid cooling of high-power chips. These plates sit on top of CPUs or GPUs, channeling coolant to rapidly dissipate heat. Copper’s superior thermal conductivity makes it ideal for this purpose, as noted by its widespread use in advanced liquid cooling systems and heat exchangers.

- Signal integrity and shielding: High-speed data interconnects within AI systems often still rely on copper, despite advancements in technology. For example, leading-edge AI accelerators use multi-chip modules where high-speed copper connectors link chiplets together. These tiny copper interposers, also known as spring contacts, maintain signal integrity at very high frequencies.

- Structural and modular applications: In some cases, copper even shows up in mechanical roles. Its density and sturdiness can add stability to specific assemblies. For instance, heavy copper brackets or busbar frames that also conduct current and double as support structures. When racks are densely packed, engineers sometimes design custom-shaped copper parts to fit into available space, serving a dual purpose, such as acting as a structural member that carries current or provides thermal mass.

See PMi2’s own insights on manufacturers turning to domestic sourcing for CNC-machined parts.

Machining Challenges Unique to Copper

Working with copper is infamously challenging for machinists. Unlike harder metals, copper’s physical properties can make precision machining and fabrication quite difficult. Machining copper requires careful process adjustments to achieve the desired results.

- Material behavior and machinability: Copper is soft, ductile, and “gummy,” which means it doesn’t cut as cleanly as steel. Standard cutting can lead to burr formation and sticky chip adhesion, resulting in crisp edges rather than smooth ones. Copper tends to form a built-up edge on tools because the material adheres to the cutting edge, causing rough finishes and burrs.

Its high thermal conductivity rapidly draws heat into the tool, which can cause cutters to overheat or wear out more quickly. Tools also dull quickly because copper’s softness still abrades tooling. - Surface finish and dimensional stability: Achieving a smooth, consistent surface on copper is more complicated than it looks. The same gummy behavior that causes burrs can also cause drag marks or an uneven finish. Copper often oxidizes when exposed to air, resulting in discoloration or a tarnished layer on machined surfaces. Surface oxidation and contamination can be an issue for electrical or thermal contact surfaces.

Many copper data components require extremely tight tolerances, particularly for thermal interface flatness or press-fit connectors. Maintaining dimensions within specification is challenging when copper can warp slightly as stresses are relieved during machining or subsequent processing. - Process complexity and cost drivers: Because of copper's inherent metal properties, machining often requires slower, deliberate processing. Machinists may need conservative passes to prevent damage to parts. Machining copper requires specialized tooling. Carbide or polycrystalline diamond anti-stick like TiAlN or diamond-like carbon (DLC) prevents material welding and ensures clean cuts.

Even with good tools, chip evacuation and cooling remain a challenge. Copper chips don’t break cleanly and can clog flutes, so high-pressure coolant and optimized toolpath strategies are essential. This adds complexity. Compared to aluminum or mild steel, copper tends to drive up scrap rates and requires tighter process control to maintain yield.

CNC Equipment and Techniques for Copper Components

Modern machine shops utilize advanced CNC equipment and innovative techniques to overcome the challenges of copper.

Companies, such as PMi2, that specialize in copper machining services, including CNC copper AI component production, invest in the right tools for the job.

High-performance CNC machines

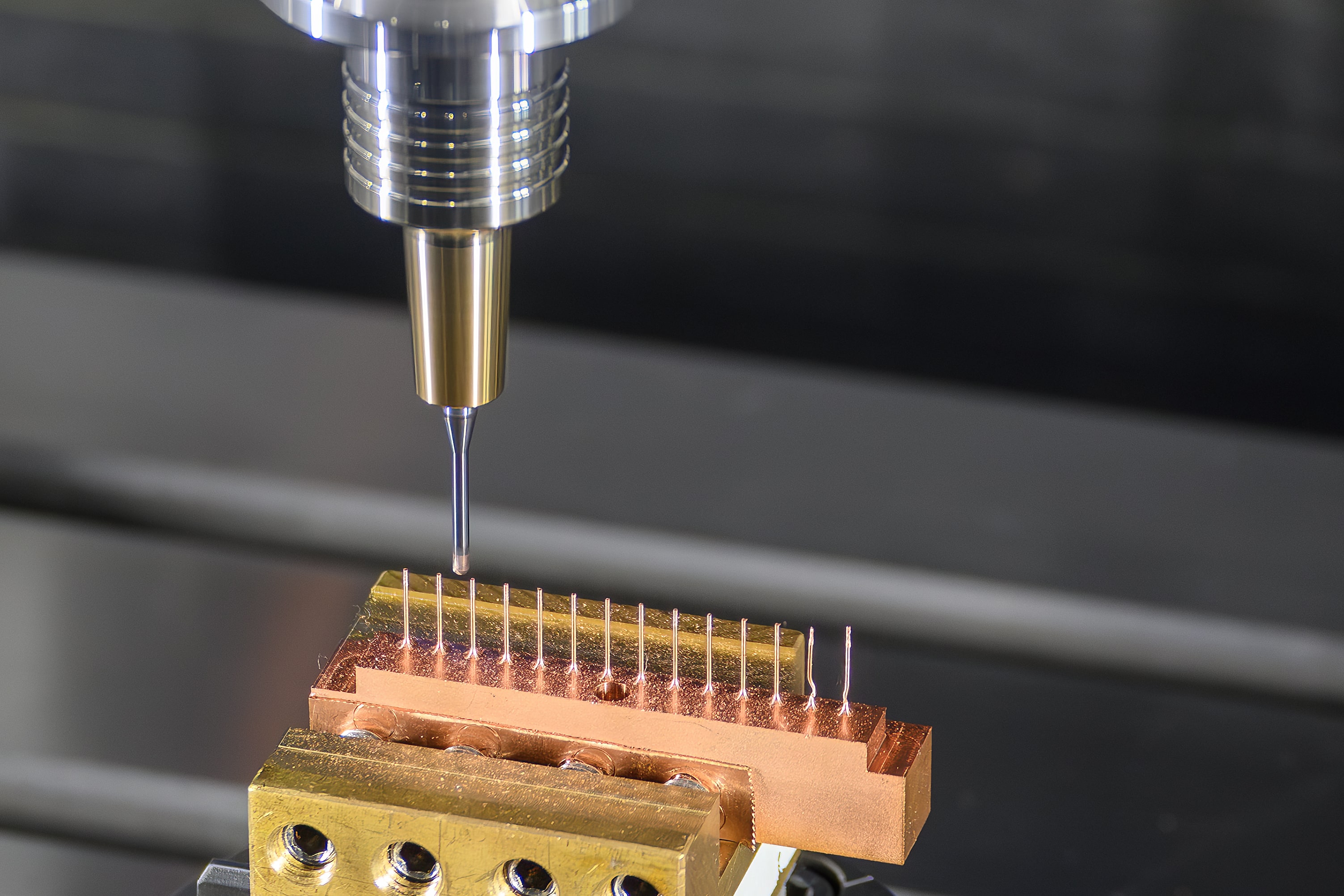

Machining copper components for AI data operations demands advanced CNC systems built for precision, speed, and stability.

- High-speed CNC milling centers: Deliver fast, stable cutting with excellent vibration damping to prevent smearing.

- Multi-axis CNC machines: Enable the complex milling of intricate housings or busbar shapes in a single setup, resulting in greater accuracy.

- Swiss-style CNC lathes: Produce fine details in custom copper fasteners and standoffs with exceptional precision.

- Wire EDM machines: Cut intricate copper profiles or slots with minimal cutting forces or burrs, maintaining tight tolerances.

- Rotary surface grinders: Resurface build plates or large copper sheets to ensure flat, smooth surfaces for consistent machining.

These machines form the backbone of copper fabrication for AI data centers, ensuring every part meets exacting specifications.

Specialized tooling and fixturing

Selecting the right cutting tools and fixturing systems is essential for achieving precision and consistency in copper machining.

- Carbide tools with coatings (TiAlN, ZrN, diamond) – Minimize material sticking and extend tool life.

- High-helix end mills and polished flutes – Improve chip evacuation and maintain clean cuts.

- Adaptive fixturing (soft jaws, vacuum chucks) – Secure thin-walled parts while minimizing deformation and stress.

- Modular fixture systems – Ensure repeatable setups for complex parts, enhancing workflow efficiency.

- High-pressure coolant and lubrication systems – Cool tools, flush chips, and prevent overheating during cutting.

These tooling, part-holding, and colling solutions deliver smoother finishes, tighter tolerances, and more reliable copper components.

Automation and AI integration

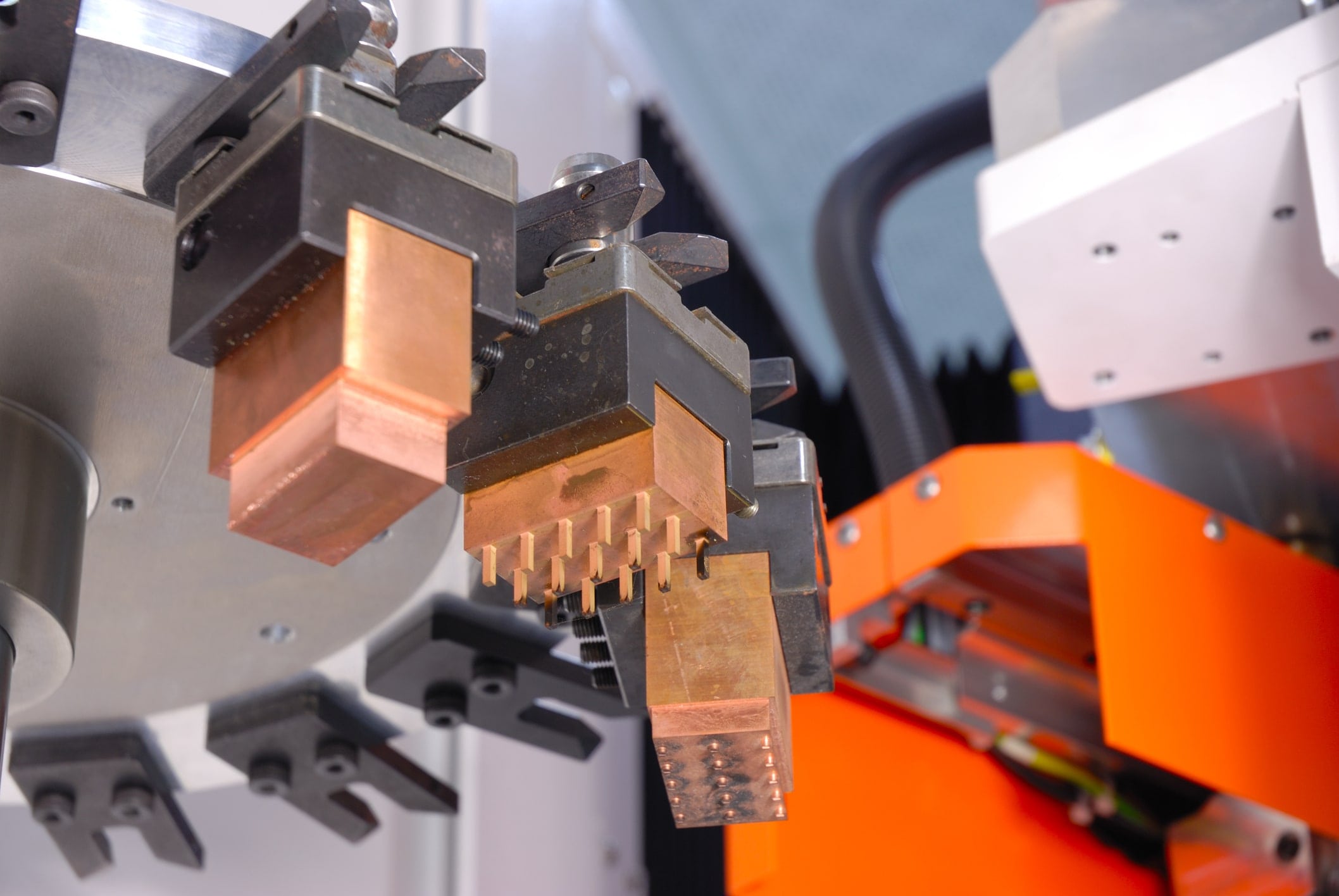

Copper component manufacturers are pushing for speed, precision, and consistency. As demand grows and tolerance requirements become more stringent, manufacturers are turning to automation and AI to stabilize output and reduce risk. These technologies are no longer experimental. They’re becoming essential across the shop floor.

- Robotic part handling loads heavy copper workpieces into CNC machines and removes finished parts, improving safety and throughput.

- AI-assisted CNC programming analyzes past machining data to recommend cutting parameters, reduce tool wear, and flag potential defects.

- Inline metrology uses laser scanners or touch probes to measure parts during production, instantly verifying dimensions and providing real-time data to adjust the process.

Companies like PMi2 are exploring these advanced techniques, from robotic integration and automated QC to AI-enhanced toolpath planning, to improve how copper parts are produced.

PMi2’s Automation Solutions team has deployed robotic machine tending and automated inspection systems for precision manufacturing.

Precision Machining Strategies for Copper Components

Copper is soft, sticky, and thermally conductive, making it difficult to cut cleanly and consistently. Tool wear accelerates, chips clog flutes, and surface finish degrades rapidly without tight process control. To hit spec and maintain yield, manufacturers must optimize every step, from tool selection to quality checks.

Considerations

- Optimized tooling and process parameters: The first step is selecting the right cutting tools and dialing in the CNC parameters for copper’s unique behavior. Shops use rigid carbide or PCD tools with very sharp cutting edges to slice through copper cleanly.

- Surface finish and post-processing control: Achieving the ideal surface finish on copper requires precision cutting and meticulous post-processing for smoothness, conductivity, and durability. After machining, manufacturers typically refine surfaces using electropolishing, buffing, or vibratory polishing. They then deburr and apply anti-oxidation treatments such as passivation, protective coatings, or thin nickel or tin plating to preserve conductivity and appearance.

- Integrated quality assurance: Given the tight tolerances and performance requirements, quality control is woven into every step of copper machining. Progressive shops don’t just inspect at the end. They incorporate checks throughout the process. For example, CNC machines may use touch-probe measurements on critical features right after cutting, verifying dimensions before the part is unclamped. High-precision coordinate measuring machines (CMMs) and even machine-vision systems can verify complex geometries and surface profiles.

Resurfacing Build Plates: A Hidden Cost Driver in Copper Part Production

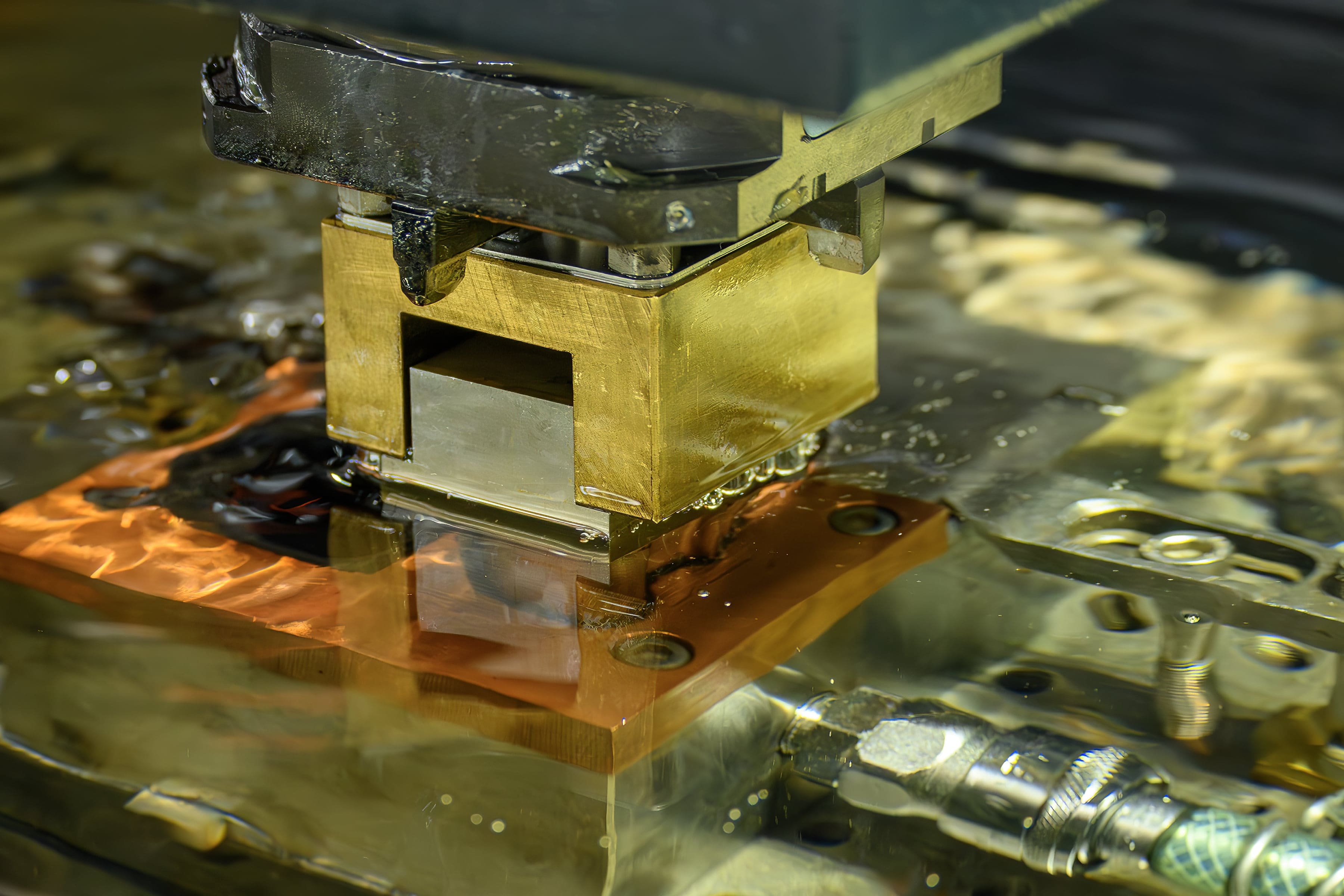

Copper 3D printing is gaining traction in data center cooling, especially for cold plates and busbars with complex internal geometries. These parts often rely on additive or hybrid workflows that start on build plates.

Maintaining those plates adds cost. Surface wear affects print accuracy, adhesion, and downstream workholding. Resurfacing takes time, and repeated cycles increase the risk of scrap and setup delays.

In metal additive manufacturing, like printing a copper heat exchanger, the print builds on a metal plate that must be flat and clean. The surface condition of the build plate directly impacts part adhesion, dimensional accuracy, and the ease of part removal.

If the plate is warped or scarred, a printed copper component may warp or fail to build correctly. Even in subtractive machining, a fixture plate needs a pristine surface to hold parts accurately. Over time, however, these plates degrade.

Surface integrity challenges

Build plates degrade from repeated thermal cycling, mechanical stress, and metal spatter during printing. Build plates warp, become pitted, and develop surface roughness after repeated exposure to heating and cooling during the build process. Over time, this wear turns a once-smooth plate into one marked by scars and low spots, compromising print adhesion and dimensional accuracy.

Oxidation and powder buildup also contaminate plate surfaces, making cleaning and resurfacing essential for maintaining integrity. Regular plate maintenance ensures the quality and reliable copper part production.

Resurfacing methods and frequency

Resurfacing a build plate involves restoring its flat, smooth surface, typically by removing a thin layer of material. There are a few ways to do this. Many shops use a rotary surface grinder or large CNC mill to skim-cut the plate, removing perhaps a few thousandths of an inch to eliminate pits and warping.

Others might lap or lightly polish the plate to restore surface smoothness. Chemical cleaning can remove oxidation or powder residue, but typically, a physical resurfacing is required to fix geometry issues.

The optimal frequency of resurfacing depends on usage; some high-throughput operations might resurface a plate every 5–10 builds, whereas others do it only when a problem is noticed. Best practice is to monitor build success rates and plate condition and proactively resurface before any severe defects occur.

Operational and cost implications

Resurfacing build plates adds cost through machine time, labor, and material removal, but it’s far cheaper than scrapping failed prints or replacing plates. Rotating spares can avoid downtime.

Many machining service providers offer scheduled swap-and-resurface programs, ensuring consistent availability without the need for investment in grinding equipment. Factoring resurfacing into budgets highlights its strong ROI, as regular maintenance prevents failures, minimizes delays, and extends plate life.

Look at “5 Business Advantages of Resurfacing Metal Additive Build Plates” for insights into how resurfacing extends plate life and cuts costs.

Comparing In-House vs. Outsourced Copper Manufacturing

Companies making copper components for AI data centers are choosing between building in-house machining capabilities or partnering with specialized vendors. Each has its strengths: more control and customization on one side, faster turnaround and deep expertise on the other.

Many teams blend both, combining internal precision with external scale while closely monitoring supplier risk and operational complexity.

Benefits of In-House Machining

Internal fabrication maintains control and agility.

- Direct collaboration: Engineers and machinists work side by side, enabling quick design tweaks and tighter tolerances.

- Quality oversight: Standards for finish, inspection, and handling stay within your control.

- Faster prototyping: In-house teams can iterate on designs quickly without supplier delays.

- Flexible scheduling: Reduced reliance on supplier timelines helps minimize production bottlenecks.

- IP protection: Sensitive designs and proprietary methods remain secure within your organization.

Benefits of Outsourced Machining

Partnering with specialized vendors offers efficiency and scalability.

- Expertise and equipment: Vendors like PMi2 possess advanced CNC systems and extensive experience in copper machining.

- Lower capital costs: Avoids significant investments in machines, tooling, and staff.

- Scalable output: External shops can add capacity or shifts to meet spikes in demand.

- Variable costs: Pay only for production, not for maintaining a full-time shop.

- Global reach: Vendors in multiple regions shorten shipping times and support distributed data center projects.

Risks of Multi-Supplier Workflows

Using multiple vendors can introduce inconsistency and coordination challenges.

- Spec interpretation differences – Suppliers may apply tolerances or finishes differently.

- Communication gaps – Design updates and engineering changes risk being lost in translation.

- Unpredictable lead times – Delays at one supplier can stall the entire assembly.

- Quality assurance variation – Inconsistent QA processes can lead to fit or performance issues.

Strategic Considerations

Choosing the right model depends on business priorities.

- Cost modeling: Compare vendor pricing with fully burdened in-house costs, including labor and equipment.

- Scalability: Evaluate whether your shop can expand quickly enough for future demand.

- Talent availability: Skilled copper machinists are rare; vendors may have deeper expertise.

- Timeline: Tight project schedules may favor established supplier networks.

- IP sensitivity: Retain in-house control for proprietary designs; outsource standard parts for efficiency.

A hybrid approach combining in-house prototyping with outsourced production often delivers the best balance of cost, speed, and control.

Data Center Industry

Accelerate your mega data center deployment with PMi2's precision machining and contract automation solutions

Explore PMi2's expertise.

Trends Shaping Copper Component Manufacturing

As AI infrastructure expands, copper manufacturing is being pushed to evolve. Companies are exploring faster, more scalable ways to meet demand while staying ahead of performance requirements.

Innovation isn’t optional. It’s baked into the next wave of growth.

- Additive and hybrid manufacturing: 3D metal printing is making inroads for producing copper parts. Recent advances enable printing of high-purity copper that traditional machining can’t easily create. We’re also seeing hybrid approaches, where a copper part is printed to get complex internal features, then critical surfaces or threads are machined to precise tolerances. This combination leverages the best of both worlds.

- Modular and scalable component design: Data center architects are advocating for more modular designs, not just at the building level but for the components themselves. This means copper power blocks or busbar assemblies that can be standardized and scaled easily.

- Automation and AI-driven optimization: Automation plays a significant role in manufacturing, and its use is only growing. For copper component production, we expect more AI integration in both machining and quality control.

- Sustainability and supply chain innovation: As demand for copper grows, so does the need to make manufacturing more sustainable. Companies are refining machining processes to use less energy and reduce waste. In-house recycling is becoming standard practice, with copper chips collected, repurposed, or melted down to feed the next production run.

Why Precision Is Non-Negotiable in Copper Machining

The following points show why precision in copper machining is critical to the performance and reliability of AI data center infrastructure.

- Copper components are central to AI data centers, carrying enormous electrical loads, cooling high-temperature chips, and enabling high-speed connections.

- These parts face extreme demands, operating under high current, high heat, and tight space constraints.

Copper’s complex characteristics amplify the challenge, making precision not just desirable but mandatory. - Even slight deviations in a copper busbar can cause voltage drops or unsafe heating.

- If a cold plate isn’t perfectly flat or contains machining debris, processors can overheat and fail.

- Tolerances, surface quality, and consistency are directly tied to overall system reliability.

With so much at stake, companies like PMi2 and other copper fabricators emphasize precision at every stage of manufacturing.

Strategic Imperatives for Manufacturers

For manufacturers involved in making copper components, investing in precision machining capabilities and rigorous QA is imperative. This may include upgrading to better CNC machines or higher-end tooling, as well as training staff specifically for copper work. It also means anticipating challenges. Innovative manufacturers plan for tasks such as build plate resurfacing and burr removal as part of their production process.

Modeling those extra steps into cost and timeline estimates ensures there are no surprises. Companies should also carefully evaluate the balance between what they produce in-house and what they outsource. If you don’t have the means to achieve the required precision on a complex copper part, it’s wiser to partner with a specialist than to deliver subpar components.

The scalability of your approach matters too, as AI deployment grows, can your manufacturing process maintain quality at a higher volume? These strategic choices will determine whether you can meet the industry’s stringent needs or fall behind.

Treat Copper Like Infrastructure

As demand for copper components in data centers grows, it’s time to pressure-test workflows. Where are the delays, inconsistencies, or quality dips? A focused audit and solid benchmarking can reveal whether automation, tooling, or process changes will actually improve output.

Benchmarking ROI is critical. Investments in better equipment or training often pay off quickly by cutting downtime and rework. Procurement and engineering teams should align on sourcing, not just by price, but also by the ability to consistently meet performance-critical specifications.

Design and manufacturing teams must align early to ensure copper components meet precision requirements without delays or rework. Busbars, cold plates, and connectors aren’t just hardware. They’re critical to data center performance.

As demand grows, the leaders will be the ones who treat these components as strategic assets. Precision, reliability, and process control aren’t extras. They’re what define a high-performance data center.

Let us help you bring your data center parts production online.

Contact Us

Working With Us

Learn how we support customers from day one, from machining to automation, design services, and more.

Contact UsFAQS

Machining copper requires controlling burr formation, chip adhesion, and tool wear due to the metal’s ductility and softness. High thermal conductivity also causes rapid tool heating, necessitating specialized tooling, coatings, and high-pressure cooling to maintain surface finish quality and dimensional stability under tight tolerance demands.

Robotic machine tending, AI-assisted CNC programming, and automated inspection enable faster throughput and lower scrap rates. AI optimizes toolpaths dynamically based on real-time feedback, preventing defects and extending tool life, which is crucial for managing the challenging machining properties of copper.

Multi-stage measurements using coordinate measuring machines (CMMs), laser scanning, and pass/fail vision systems verify intricate features and surface finishes. This rigorous approach ensures tight tolerances for thermal interfaces and electrical contacts are met, critical for avoiding failure modes in AI infrastructure.

Advanced carbide tooling, equipped with specialized coatings, is utilized in conjunction with controlled feed rates and high-pressure coolant systems. Robotic deburring further assists in producing smooth finishes, thus minimizing production downtime and improving overall quality consistency.

Typical failure mechanisms include rough surface finishes, edge burrs, and warping, which can lead to increased electrical resistance or thermal inefficiencies. Quality assurance protocols, precise surface finishing, and predictive maintenance of tooling effectively reduce these risks and improve component reliability.