Cobots Bring Flexibility, Robots Bring Power, Manufacturers Need Both

Manufacturing has entered a period where automation is strategic, not optional. Industrial robots have been transforming factories since the 1960s, accelerating production and improving quality.

Adoption has become widespread. In 2023 over 4.28 million industrial robots were operating in factories worldwide, and the global average robot density reached 162 robots per 10,000 employees, more than double the level just seven years prior.

These numbers reveal how crucial robotics has become for manufacturing competitiveness. Over the decades, leaps in technology have expanded what automation can do.

At the same time, manufacturers’ needs are evolving. Labor shortages and demand for higher productivity push even small and medium-sized companies to consider automation. This is where a newer class of robots enters the picture with collaborative robots, or cobots, designed to work safely alongside people.

This article demystifies standard industrial robots and collaborative robots, explaining why each was developed and how to evaluate which might fit your operation.

Industrial Robots Explained

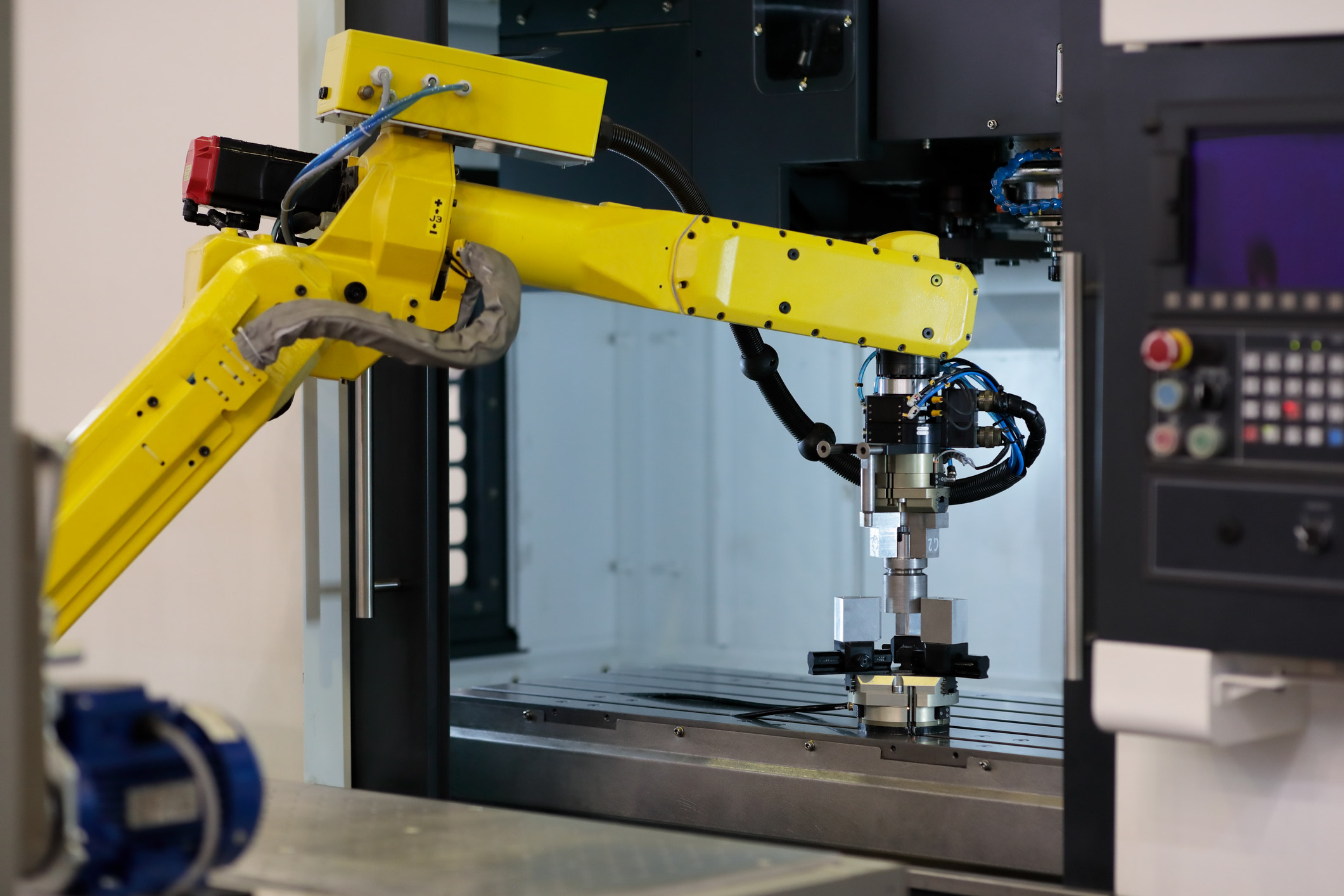

Industrial robots are the classic robots most people picture on a factory floor. They’re generally a large, powerful, programmable machine designed to perform tasks like welding, painting, assembly, or material handling with high speed and precision.

They are automatic, reprogrammable manipulators capable of moving tools or parts in multiple axes, which makes them versatile for repetitive tasks.

Industrial robots typically have a fixed installation in a manufacturing cell and often operate isolated from workers behind safety fences or cages to protect employees from their sheer speed and force.

Industrial robots handle heavy payloads on the production line and achieve repeatable accuracy within fractions of a millimeter, making them ideal for high-volume, high-precision production.

Key Benefits of Industrial Robots

Advantages of industrial robots include speed, payload capacity, precision, and repeatability. They can work blindingly fast, far faster than a human or a collaborative robot, which is why they excel at high-throughput tasks on fast-moving manufacturing lines.

Industrial robots can be massive, with models capable of lifting hundreds of pounds or reaching long distances. This muscle makes them well-suited for heavy-duty jobs like lifting engine blocks or welding car frames that smaller robots cannot handle.

Industrial robots also offer outstanding positional accuracy and repeatability. They can perform the same motion thousands of times with the same result, which ensures consistent product quality.

Collaborative Robots (Cobots) Explained

Collaborative robots, often called cobots, are a newer breed of industrial robot designed from the ground up to work in collaboration with humans. Unlike their bigger cousins, cobots are smaller and lighter manipulators with built-in safety features, allowing them to operate in a shared workspace with people.

After a proper risk assessment, a cobot can often work side-by-side with human workers without bulky safety fencing, because the robot itself is engineered to be safer.

Cobots incorporate features such as force sensors, collision detection, and limited speed settings that cause them to automatically slow or stop if they bump into an unexpected object or person.

A collaborative robot is an industrial robot designed in compliance with ISO 10218-1 and intended for collaborative use. This means it meets stringent safety requirements for power and force limiting.

Despite their smaller size, cobots can perform many of the same tasks traditional robots do, but typically handle lower payloads and operate at slower speeds.

They excel in tasks that require a degree of flexibility or human interaction. For instance, in an assembly operation, a cobot might hold a part steady while a person fastens screws, merging human dexterity with robotic strength.

Key advantages revolve around safety, flexibility, and ease of use. Because cobots are intended to work near people, they are designed with smooth, rounded surfaces and smarter control software to minimize risk.

Most models have an intuitive human-machine interface (HMI) or even allow “teaching” by hand-guiding the robot’s arm, which makes programming simpler than complex coding often required for traditional robots.

They are also physically adaptable. A cobot might be bolted to a mobile cart or placed on a workbench, allowing it to be easily moved to different tasks as needs change.

Key Differences: Cobots vs. Industrial Robots

When comparing collaborative robots to standard industrial robots, it helps to break down their differences across several criteria, focusing on safety, flexibility, ease of use, cost, performance, integration, and applications to give you a clear picture of where each one excels and where each has drawbacks.

Safety

Safety defines the difference between cobots and traditional industrial robots. Collaborative robots are built with safety “baked in.”

They utilize force-limited joints, sensors, and smart software to prevent accidents. This design lets cobots work right next to humans on the factory floor without physical barriers under the right conditions.

In contrast, standard industrial robots pose significant hazards to nearby people due to their high speed and force. A typical industrial robot must be kept in a segregated area so that it cannot accidentally strike a worker.

Any time an operator needs to approach the robot, the system must be powered down or put in a safe mode. Industrial robots and humans do not share the same workspace during operation. They work sequentially or in isolation for safety.

Flexibility & Adaptability

When it comes to flexibility, cobots are generally more adaptable than their traditional counterparts. A collaborative robot is usually easier to reprogram and redeploy. After proper commissioning, an operator can teach it a new task or move it to a different workstation with minimal downtime.

Manufacturers handling high-mix, low-volume production or frequently changing processes find this agility useful. For example, a cobot might spend the morning doing a packaging job, and later be re-assigned to assist in machine tending, with a quick reprogramming session in between.

Industrial robots, on the other hand, lack that flexibility and require more expert reprogramming to change their task or product inputs.

FURTHER READING: How Automation is Powering the Next Era of Automotive Manufacturing

They tend to be dedicated to specific processes for long periods. Reconfiguring an industrial robot often means significant downtime and skilled programmers or integrators.

For large manufacturers making the same product in huge volumes, this isn’t a problem. A car factory, for example, will run an industrial robot welding the same chassis part for years. But for smaller companies or those with dynamic product lines, this rigidity is a pain point.

Ease of Use & Programming

Because of their history in high-tech automation, industrial robots have typically required specialized programming knowledge.

Integrating an industrial robot into a production line can be a complex project, involving systems integration, peripheral equipment, and trial-and-error to fine-tune motions. This complexity means companies require skilled automation engineers or robot programmers on staff or contracted support.

Collaborative robots were conceived to break down this barrier.

Cobots are built to be user-friendly, lowering the learning curve for automation. Many cobots can be programmed through an HMI or even by demonstration. For example, an operator can physically move the cobot arm through the desired motions, and the cobot’s controller records the positions.

Companies see this simplicity as an advantage because they don’t need high-demand dedicated robotics experts. However, cobots still require expert integration and proper risk assessments to ensure they are safe to use in close proximity to personnel.

Cost & ROI

Cost is often the deciding factor in automation decisions, and here, collaborative robots frequently have an edge for small and mid-sized applications.

Traditional industrial robots tend to have higher upfront costs. Installing one is often a capital project, with significant planning and custom work.

Cobots, in contrast, generally have higher purchase cost but the higher cost of the robot can be offset by substantially lower deployment costs due to reduced programming time, application flexibility, and the need for less physical guarding in the system.

The cost of any given cobot is substantially higher than that of its similarly sized standard robot. The offsets may be in the lower cost of integration. This would include less programming time, less physical guarding and safety controls in the system, etc.

Cobots often achieve a faster ROI. In fact, collaborative robots have an average return on investment of about one year in many cases, meaning a cobot can pay for itself in 12 months through labor savings and increased output.

By contrast, a traditional robot cell might take several years to recoup its cost. For a CEO or owner evaluating automation ROI, this is the compelling advantage of opting for cobots.

That said, industrial robots can deliver massive productivity in the right scenario, which translates to long-term cost efficiency for high-volume production.

If you’re making millions of identical products, a fast industrial robot can significantly drive down per-unit costs after the initial investment if the scale and volume justify it.

Many smaller manufacturers don’t have that volume, which opens the door for cobot automation. It’s also worth noting that maintenance and operation costs differ because cobots are designed with simpler maintenance in mind and often use less power, while large robots might require more upkeep.

Comparing Performance

When it comes to performance metrics like speed, payload capacity, and duty cycle, standard industrial robots are the undisputed champs.

These machines are built for speed. They move and cycle through tasks at rates a collaborative robot typically can’t match.

Cobots, by design, move more slowly, especially when in cooperative modes with humans, because they must limit force and momentum for safety. If you need “blink and you’ll miss it” speeds, a cobot would likely be too slow.

Payload is another differentiator.

Many collaborative robots handle payloads of 5–20 kg. In contrast, industrial robots exist in all sizes, including giant models that can lift 100 kg, 200 kg, or more.

This means tasks involving very heavy objects are exclusively the domain of traditional robots.

Even for moderate weights, industrial robots usually have more strength in reserve, which can translate to better endurance and longevity when carrying out repetitive motions at high loads.

Duty cycle and durability also generally favor industrial robots. They are engineered to run at full tilt, 24/7 in harsh industrial environments, sometimes for years between major overhauls.

While cobots are robust, their smaller motors and frames may wear faster under continuous high-stress use, and they might require more frequent breaks or shorter duty cycles to avoid overheating.

Integration & Space Requirements

Deploying a robot is not just about the robot itself. It’s also about the footprint and fitting it into your existing operations. Collaborative robots often make integration easier. Because cobots are safe around humans, they can be installed into an existing assembly line or work cell without massive reconfiguration.

Standard industrial robots, conversely, often require significant space and infrastructure. They are usually larger and require allocating space for their safety cage or light curtain boundaries, robot controller cabinet, and possibly additional guarding or material handling equipment.

A traditional robot workcell can take up a considerable chunk of factory floor space.

Installing a big robot cell might be a challenge for businesses pressed for space. Integration of an industrial robot might also involve more downtime before startup for installing the equipment and safety protection, and possibly restructuring workflows

Uses, Applications, and Industries

Both collaborative and industrial robots find uses in various industries, but there are clear patterns in where each type excels.

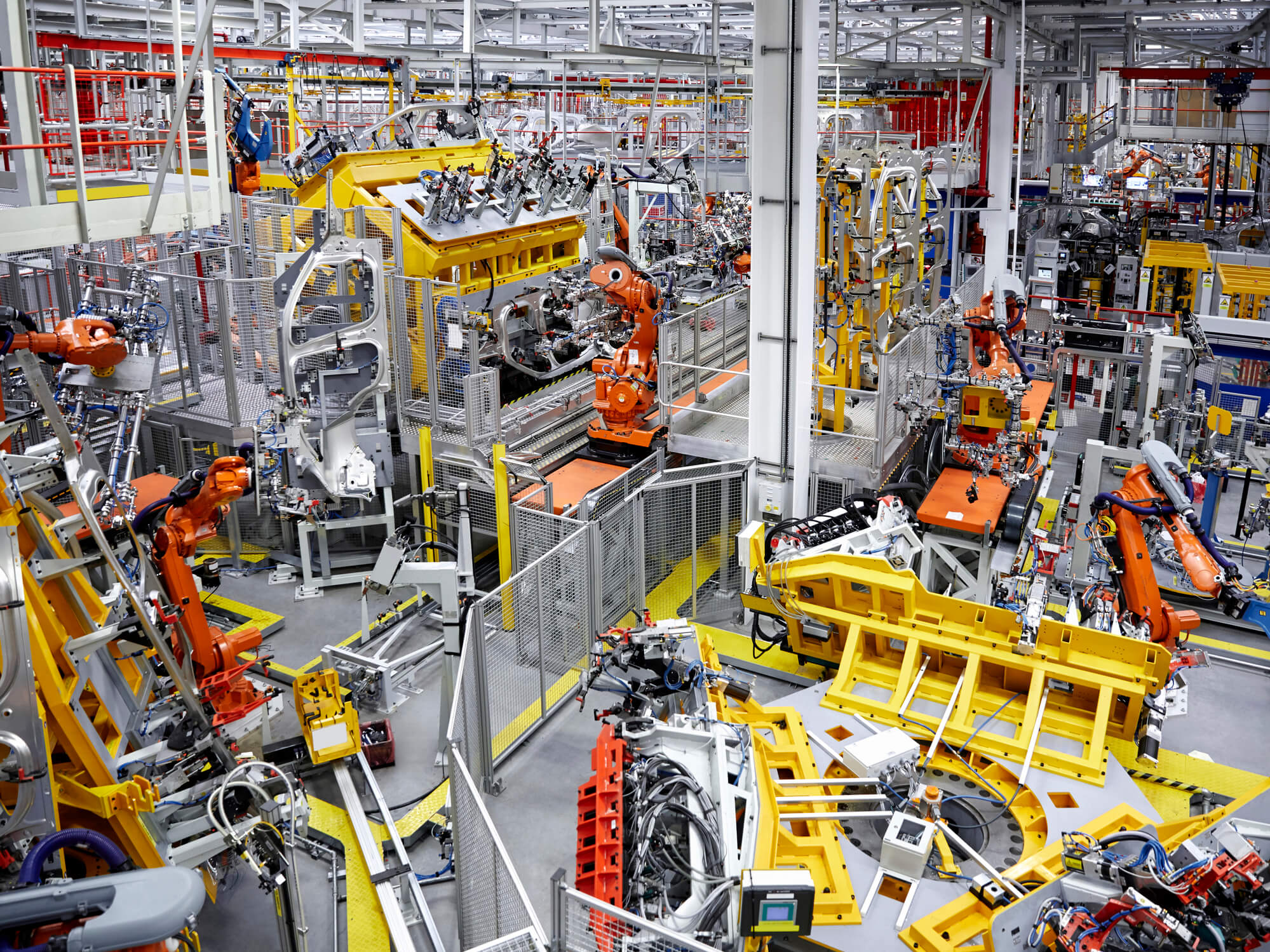

Industrial robots have long dominated heavy manufacturing sectors like automotive and electronics.

In the automotive industry, for example, it’s common to see huge robotic arms welding car bodies or painting vehicle frames behind safety glass, operations where high speed, precision, and repeatability are necessary.

Likewise, in electronics manufacturing, industrial robots handle extremely repetitive tasks with tight tolerances, such as placing components on circuit boards at high speed. Their precision and endurance make them invaluable in these high-volume settings.

Collaborative robots, meanwhile, have gained ground in applications that require more flexibility or human touch. Cobots are increasingly used in the food and beverage industry for tasks like packaging and palletizing products.

A cobot can pick and place food items into packages or stack boxes on a pallet in a production area where human workers are also present, improving throughput without compromising safety.

In the pharmaceutical and medical device sectors, cobots are used for light assembly, lab testing automation, or even assisting in surgeries and rehabilitation exercises.

Manufacturing, cobots often handle assembly operations, machine tending, quality inspection, and screwdriving, tasks where a human might still be in the loop for finesse or decision-making, but a robot can take over the monotonous part.

Custom Automation Solutions

Leverage our decades of expertise to integrate the production automation you need.

Automation Services

Solutions for Small and Medium-Sized Manufacturers

A special consideration is how smaller manufacturers can leverage robotics.

Traditionally, small and medium-sized enterprises (SMEs) found it difficult to adopt industrial robots. The costs were high, and the equipment required in-house expertise to program and integrate a robot cell. Collaborative robots changed the game.

Cobots are frequently marketed as “automation for small manufacturers” because their lower cost and simplicity align well with the needs of SMEs.

In fact, the International Federation of Robotics notes that the share of companies using any robots is still relatively small among SMEs, but cobots offer solutions for this segment where a traditional industrial robot might be overkill or too costly.

Many cobot applications have lower adoption requirements for programming skill, precision, and payload, meaning the total cost of ownership can be lower and the deployment easier for a small operation.

For a small manufacturer, a cobot can tackle tasks that are tedious or unsafe for employees, such as tending a CNC machine, performing simple assemblies, or packing products, without requiring a complete overhaul of the facility.

Companies can start automating one step at a time, gauging the return on investment incrementally. Also, the collaborative aspect means you don’t necessarily need to dedicate an isolated area for the robot. It can share space with workers in a small workshop.

For smaller production lines, exploring a collaborative robot could help resolve bottlenecks. Many small and medium-sized enterprises have discovered that deploying a few cobots increases output and eases labor shortages without the complexity of installing large industrial robots.

Goals, Motivations, and Pain Points by Audience

When evaluating cobots vs. industrial robots, your perspective might differ depending on your role in the organization.

Production Managers

Production Managers keep production lines running smoothly, hitting targets while managing unexpected changes and minimizing downtime.

Priorities

-

Increasing throughput

-

Reducing downtime

-

Improving safety

-

Maintaining quality

Challenges with Industrial Robots

-

Extended downtime during changeovers

-

Complex setups that don’t support agility

-

Safety concerns

Cobot Appeal

-

Flexible retraining or relocating

-

Adapt to market or order changes

-

Reduced downtime

-

Safety benefits

When Robots Are Preferred

-

Stable processes with high speed and endurance

-

Where maximizing throughput is the top priority

Production managers find that combining collaborative and industrial robots provides a balanced approach, delivering agility and high output.

Engineers

Engineers ensure all systems run reliably and are incorporated into existing workflows. They focus on the practical implementation, ensuring robots operate efficiently and can be easily maintained and programmed.

Priorities

-

Automation that is dependable and easy to maintain

-

Smooth integration with existing systems and machinery

-

Clear, efficient programming and troubleshooting

Challenges with Industrial Robots

-

Programming requiring proprietary code

-

Integrating safety PLCs and coordinating with conveyors, sensors, and other equipment

-

Specialized skills

-

Delicate tasks requiring fine force control

Cobot Appeal

-

Simplified integration

-

User-friendly programming HMIs

-

Faster deployment, easier debugging, and direct teaching

When Robots Are Preferred

-

Tasks demanding high speed or ultra-precision, where traditional robots meet exact specs despite programming complexity

Engineers are also often motivated by new technology trends and seek to stay current with advancements in robotics.

Owners / CEOs / C-Suite

Decisions at the executive level center on the bigger picture of balancing financial performance, operational resilience, and long-term growth. Owners and C-suite leaders are tasked with steering the company toward sustainable success by making smart investments that deliver measurable value.

Priorities

-

Maximizing ROI

-

Reducing labor costs

-

Future-proofing operations

-

Competitiveness

Challenges with Industrial Robots

-

High initial costs and significant capital expenditures

-

Underutilization from business downturns

-

Downtime

-

Technology uncertainty and long-term value

Cobot Appeal

-

Lower initial investment and faster ROI, often paying off within a year or two

-

Flexibility to redeploy cobots across tasks, reducing risk of underuse

-

Enhanced worker productivity, safety, and morale

-

Scalable, less risky entry point

When Industrial Robots Are Preferred

-

High-volume, core processes where large-scale automation drives strong returns

-

Large manufacturers looking to stay ahead through heavy automation

Executives favor a hybrid automation strategy, using cobots to fill labor gaps to incrementally automate operations and deploy industrial robots for high-speed, high-volume production. This approach maximizes ROI and keeps operations adaptable, ultimately supporting profitability and competitive advantage.

Industry Applications

Let’s look at a few industries to see where collaborative and industrial robots are typically applied, and how they complement each other:

-

Automotive Industry

This sector has historically been a heavy user of traditional industrial robots. High-payload robots perform spot welding, painting, and material handling of large car parts with speed and consistency. Cobots are now making inroads in automotive assembly lines, for example, assisting humans in assembling components, doing quality inspections, or handling small parts that require finesse. Cobots in the automotive sector often take on tasks in final assembly or sub-assembly processes where a human may be involved, improving ergonomics and throughput. Industrial robots still handle the heavy chassis and frame builds, while cobots lend flexibility in areas like interior assembly or testing.

-

Electronics and High-Tech Manufacturing

Electronics production often requires precise, delicate handling of components. Industrial robots are used in large-scale semiconductor fabrication and PCB assembly for their extreme repeatability. But in many electronics factories, cobots assemble small devices, perform quality testing, or apply adhesives on circuit boards. The cobots’ gentle touch and easy reprogramming are ideal for high-mix electronics manufacturing where products change frequently. They can manipulate fragile parts or connectors and can be quickly reconfigured for new product models.

-

Food & Beverage

This industry relied on manual labor for packaging and processing, but robotics offers improved hygiene and efficiency. Collaborative robots are popular in food and beverage for tasks like packaging, carton erecting, pick-and-place of food items, and palletizing finished goods. Their safety design allows them to work near food production workers without risking injury, and their flexibility adapts to seasonal products or frequent packaging design changeovers. Traditional robots are also used in this industry for high-speed bottling lines or heavy bag palletizing, but cobots have opened automation to smaller producers like craft breweries or bakeries who need a compact, safe solution.

-

Pharmaceuticals & Medical Devices

In pharma manufacturing and medical device assembly, precision and compliance with strict standards are key. Cobots are increasingly utilized in laboratory automation, pill sorting, injection molding machine tending, and assembly of medical devices. A collaborative robot might prepare test sample kits in a lab or assist a technician in compounding medications, operating safely in close quarters. In hospitals and healthcare, cobots work in patient-facing roles like rehabilitation exercises or room disinfection using UV light robots, thanks to their safety features. Industrial robots play a minor role here in bulk pharmaceutical production or packaging lines, requiring high speed in a controlled environment.

-

Logistics & Warehousing

The logistics sector has exploded with automation in recent years. Alongside autonomous mobile robots (AMRs) that ferry goods, collaborative robotic arms perform order picking, sorting, and parcel packaging. They often work at packing stations to pick individual products and pack boxes for shipping, tasks traditionally done by hand. Cobots can reduce the repetitive strain on workers in fulfillment centers by handling the grab-and-place motions, while humans handle decision-making for complex orders. Industrial robots in logistics might appear in massive distribution centers for sorting very high volumes. But the trend in warehouses is cobots working with humans to boost productivity in e-commerce fulfillment.

-

General Manufacturing & Job Shops

Both types of robots are commonly used in various industries like metal fabrication, plastics, and furniture. A small machine shop might use a cobot for machine tending a CNC mill, loading and unloading parts, because it’s easy to program for different part shapes. A larger fabrication plant might use industrial robots for heavy welding on steel assemblies, while deploying cobots for tasks like grinding, polishing, or loading smaller weld fixtures. Each industry tends to adopt the mix of robots that suits its product and volume. Importantly, many integrators (such as PMi2) service a range of industries by providing the right solution for each case – sometimes that’s a standard industrial robot cell, other times a collaborative robot or a hybrid approach.

Implementation Considerations

Adopting any robotic solution requires careful planning beyond just picking the robot model. Here are some key implementation considerations to keep in mind.

-

Safety & Compliance: Even when using collaborative robots, adherence to safety standards such as ISO 10218 and ISO/TS 15066 for collaborative robot safety is essential. Perform a risk assessment for each robotic application. Ensure proper safety sensors or emergency stop systems are in place. Collaborative robots significantly reduce the risk of injuries, though a cobot wielding a sharp tool might still need guarding. Industrial robots need complete safety fencing and interlocks. Compliance with OSHA or other local regulations is mandatory. Plan this into your implementation timeline.

-

Workforce Training: Successful automation integration involves trained operators, technicians, and engineers for running and maintaining the robot system. With cobots, training is usually quicker, but operators still need to know how to safely interact with the robot and respond if it stops or errors out. Industrial robots require more extensive training for the programming team and maintenance staff. Getting buy-in from workers is also important to emphasize that robots will take over dull or dangerous tasks, while workers can be upskilled to supervise and manage the automated cells.

-

Integration with Existing Systems: Consider how the robot will tie into your current production line and IT systems. Will the robot need to communicate with a conveyor PLC, a vision inspection camera, or a central MES/ERP system for job orders? Plan the industrial controls integration and OT networking so that the robot doesn’t become an island. For a cobot, integration might be as simple as a stand-alone workstation initially, later adding connectivity and data flow. Industrial robots often form the centerpiece of an integrated cell with multiple devices, ensuring you budget engineering time to get all components working together.

Working with an experienced robotics integrator can greatly help in this phase, as they can design the system architecture that fits your operations.

Decision Criteria – How to Choose the Right Robot

With a clear picture of the differences and use cases, the final step is deciding which type of robot is right for your needs. Here are some key criteria to evaluate when making your decision.

-

Production Volume & Throughput: If your operation requires very high throughput (thousands of parts per hour) and the process is highly repetitive, a standard industrial robot may be the better choice for speed and endurance. A cobot is often sufficient and more cost-effective for lower volumes or more moderate speeds.

-

Product Variability & Changeovers: How frequently do you change the product, task, or setup? If you run a high-mix production with frequent changeovers, the quick reprogramming and flexibility of cobots minimize disruptions. If the task rarely changes, either type can work, but the industrial robot’s lack of flexibility won’t be a drawback in that case.

-

Budget and ROI: Consider the initial investment and the expected return. Cobots generally have lower purchase and integration costs, which can be attractive if capital is limited or if you need to justify a fast ROI. Industrial robots might require a larger up-front budget for the robot, peripherals, and safety equipment, but they could yield greater output in the long run. Calculate the payback period for each option given your production metrics.

-

Technical Resources & Expertise: Do you have or can you hire in-house robot engineers and programmers? If not, a collaborative robot’s ease of use means you can get by with training your existing staff to deploy it. If you do have a strong automation engineering team or integration partner, they can handle an industrial robot project, but factor in the engineering effort required. Also, think about maintenance: who will troubleshoot if the robot goes down at 2 a.m.?

-

Facility Infrastructure & Space: Evaluate available floor space and infrastructure. In a cramped workshop with employees working in close quarters, a cobot can fit in seamlessly and work without safety fencing, whereas a traditional robot might not have room for a safe installation. Also consider the environment. Cobots integrate nicely if it’s a very clean environment or one where humans must be present, like a lab or a small assembly room. An industrial robot in an enclosure could be ideal for heavy industrial environments (foundries, very dirty or hazardous areas where no people go).

Flexible Automation Fuels Manufacturing Results

Collaborative and standard industrial robots offer opportunities for manufacturers. The right type is essential to maximize ROI and maintain competitiveness. It’s not about one being better overall, but finding the right fit for each task and context.

The best choice depends on specific production goals, constraints, and workforce needs. By understanding the strengths and limits of each, manufacturers can develop an automation strategy that enhances productivity, safeguards workers, and improves profitability. Used wisely, both cobots and industrial robots can drive manufacturing success at any scale.

FAQS

Cobots are designed to work safely alongside humans with built-in safety features, while industrial robots typically require safety cages and operate separately from people.

Cobots are better suited for low-volume, high-mix production due to their flexibility, easy reprogramming, and quick redeployment.

Cobots generally have a lower upfront cost, reduced setup expenses, and lower maintenance requirements, making them attractive for smaller manufacturers.

Cobots are designed for user-friendly programming and can often be set up by non-experts, while industrial robots usually require specialized programming skills and more complex integration.

Industrial robots excel in high-speed, high-volume, and repetitive tasks due to their speed, precision, and durability.

Industrial robots are better suited for heavy payloads and harsh environments, while cobots are typically used for lighter tasks and standard factory conditions.

Industrial robots are prevalent in automotive, electronics, and heavy manufacturing, while cobots are increasingly used in logistics, assembly, packaging, and small-batch production across many sectors.

Cobots can help address labor shortages and reduce the need for highly specialized technical staff, while industrial robots may require dedicated engineers for programming and maintenance.

High upfront costs, complex setup, significant space requirements, and the need for safety infrastructure are common challenges with industrial robots.

Cobots are designed for rapid redeployment and can often be moved and reprogrammed in a matter of hours, making them ideal for agile manufacturing environments.

Yes, many manufacturers use a hybrid approach, leveraging cobots for flexible, collaborative tasks and industrial robots for high-speed, heavy-duty operations.

Cobots often deliver a faster ROI for small and medium-sized businesses due to lower costs and quicker deployment, while industrial robots provide long-term value in high-volume settings.

Generally, no. Cobots are designed to operate safely without cages, but a risk assessment is still necessary for each application.

Key decision criteria include production volume, product variability, available budget, technical resources, and facility infrastructure